This article aims to provide a plan for the year two apprentices. It gives direction for their Low Carbon Heating Technician apprenticeship journey. In the article, I will share the planning of the year two content. I will explain how the classroom, workshop, and workplace work together. They combine to achieve the aims of the year’s journey at Bolton College. In year one, the apprentices were getting used to the apprenticeship standard and the KSB’s. They were also learning some basic skills common within the industry. By the end of year one, they could bring all this together. They could install a heat pump to a system, then fill up, flush, and test it. Year two has been developed to take this further. It aims to train and challenge apprentices to understand why these things are done. They will learn when, who, and how to perform these tasks effectively.

Classroom Activities in year 2

In the classroom we plan to cover the following content of which the topics and descriptions are listed below. (Knowledge Task – Behaviour Combined Task) Kt and BCt

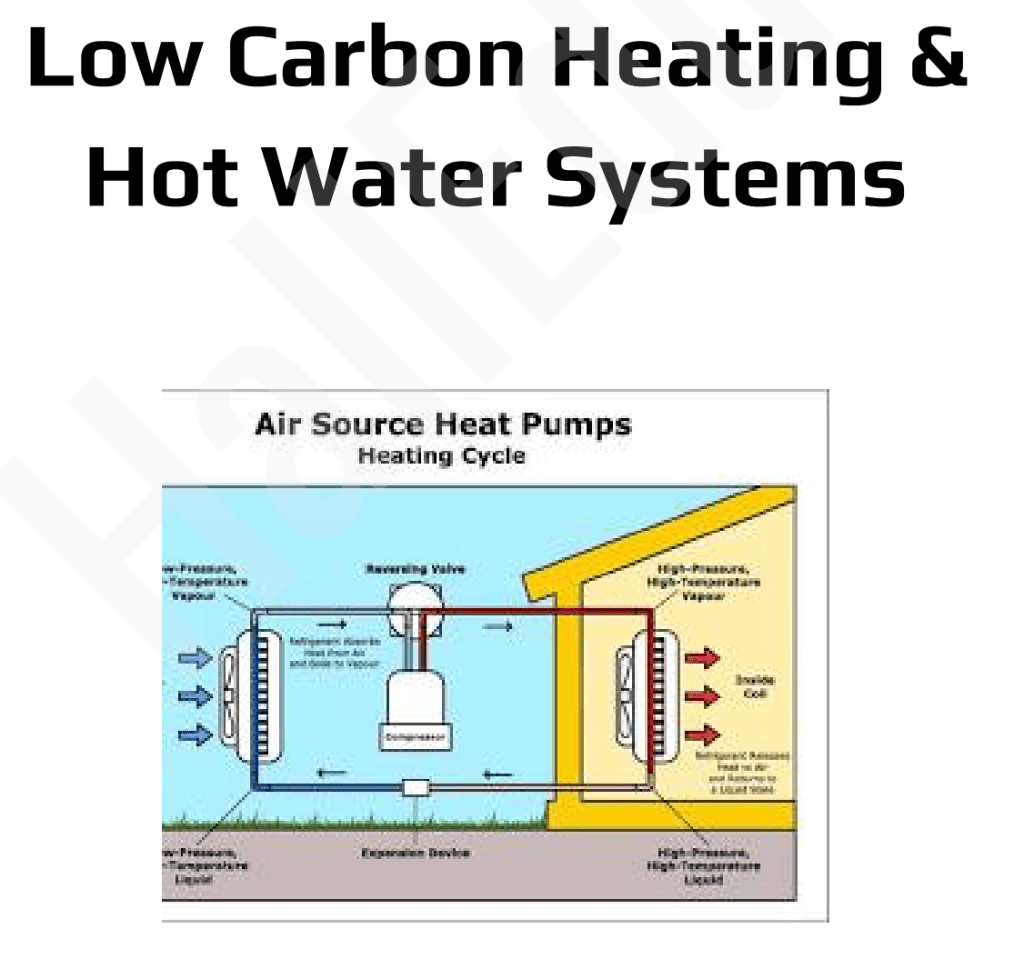

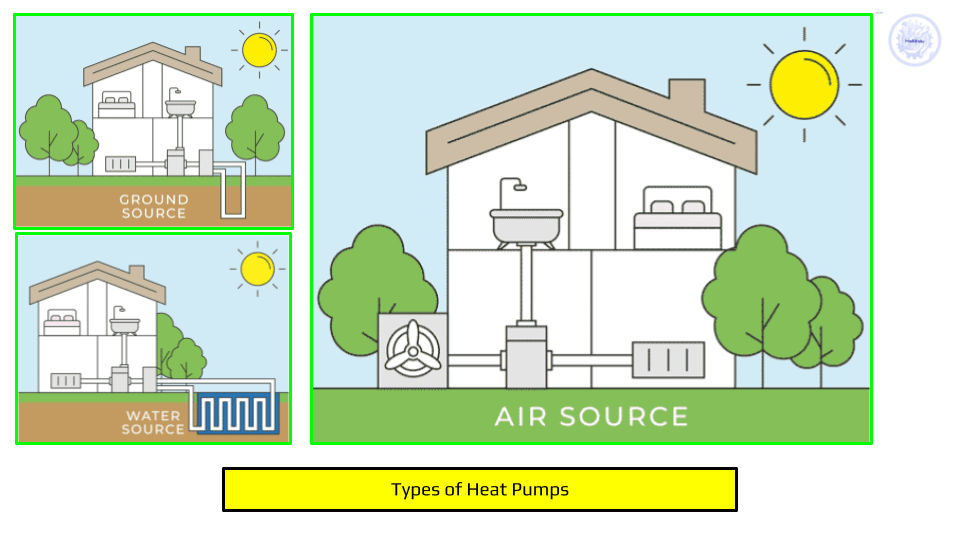

Types of heat pumps. Discover the range of heat pumps and how they are used. Understand their functionality. Explore how they can be combined, or not, with other sources. (Knowledge Task – Behaviour Combined Task) Kt and BCt

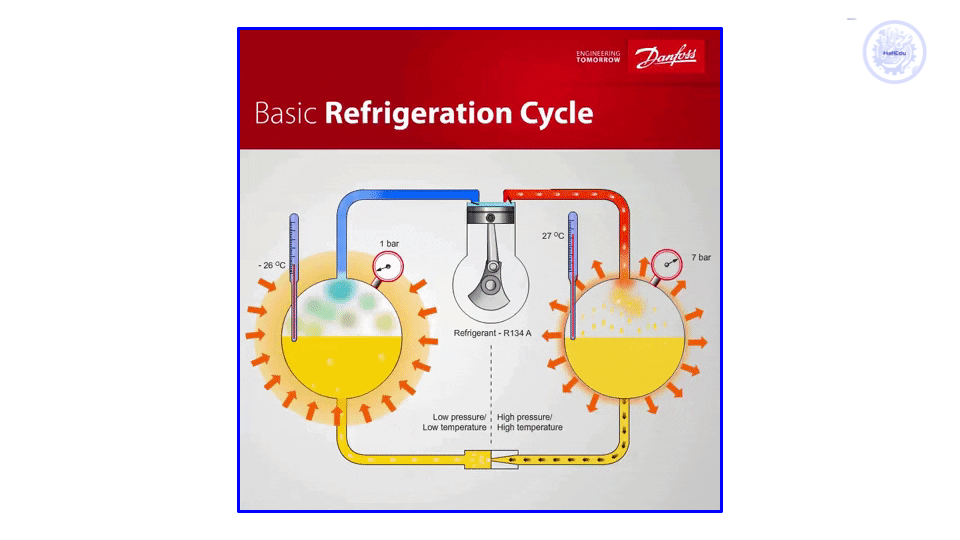

Refrigeration cycle, breadth and depth of the science of this involve discussing and experimenting. Increasing the pressure leads to an increase in temperature. Lowering the pressure results in a lower temperature. (Knowledge Task – Behaviour Combined Task) Kt and BCt

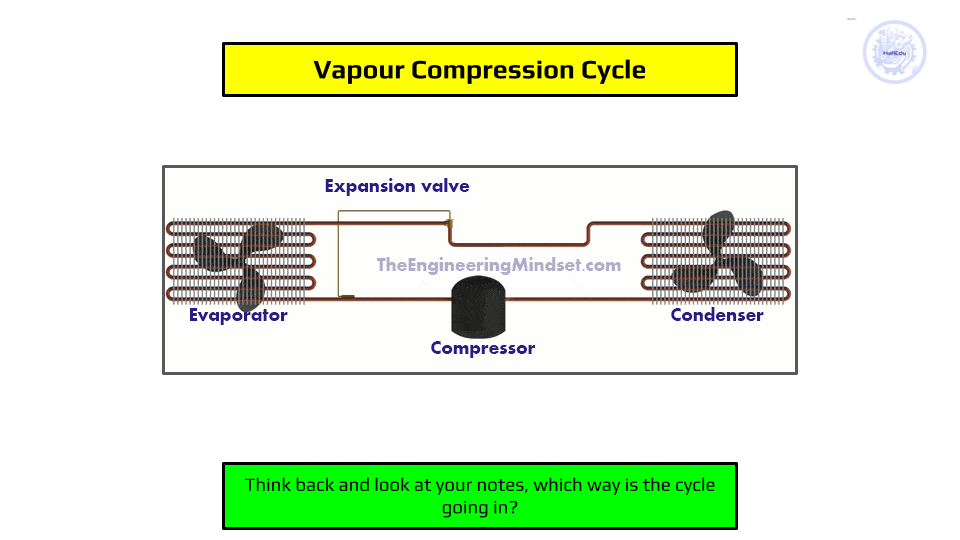

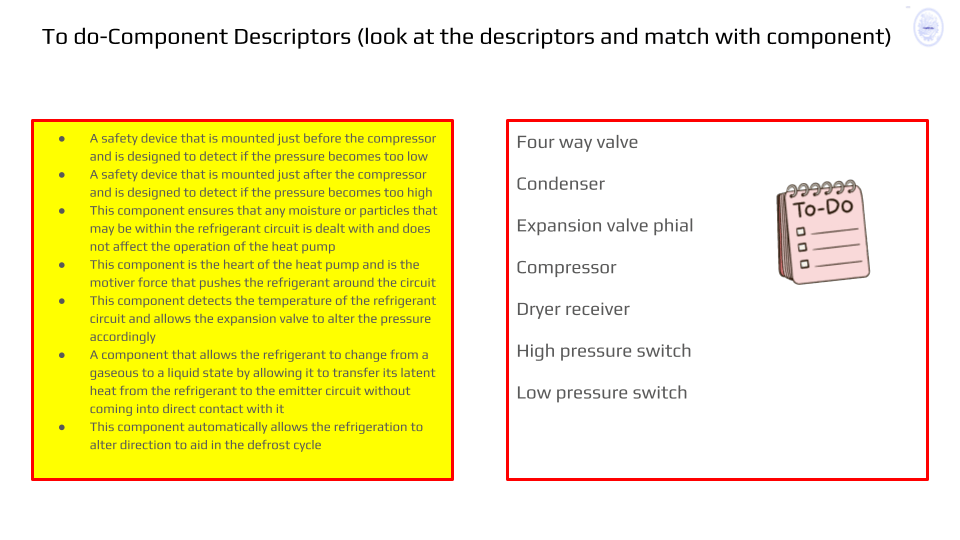

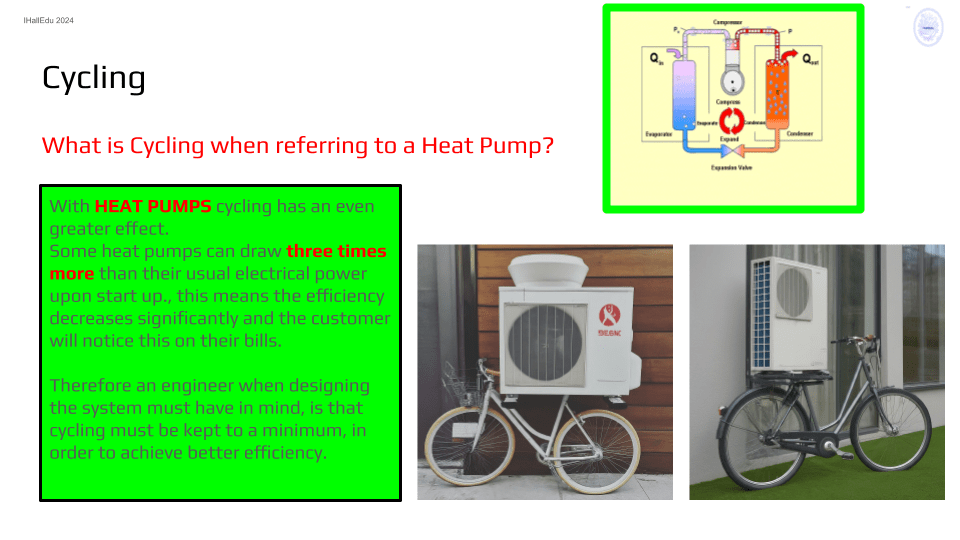

Vapour compression cycle. Understand the principles of operation of the four key parts of the heat pump. Learn what each part does. Discover which other components they are linked to and why. (Knowledge Task – Behaviour Combined Task) Kt and BCt

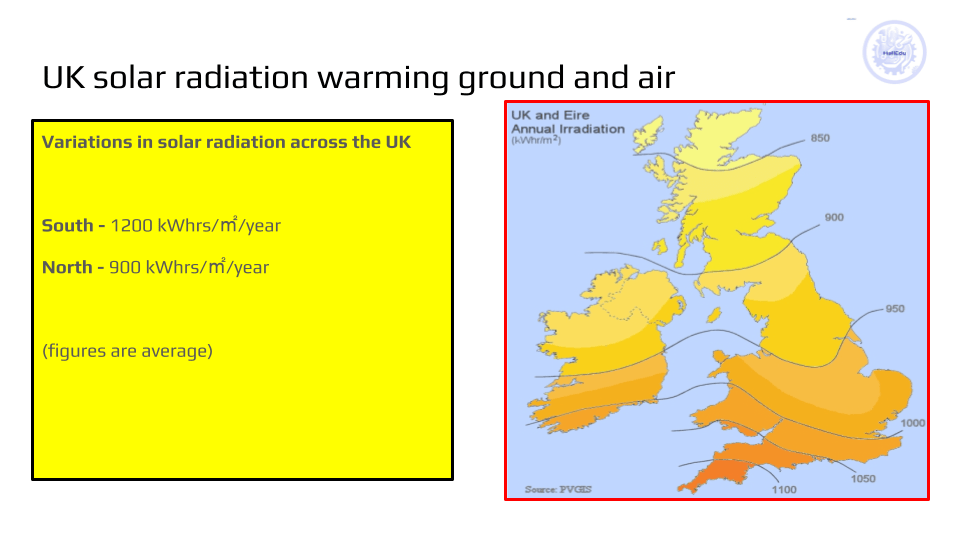

Where is the energy from? Discussions on the impact of solar gains occur around the UK. The impact on heat pump installations varies when sited at different locations. In addition supplementary sources of heat when required. (Knowledge Task – Behaviour Combined Task) Kt and BCt

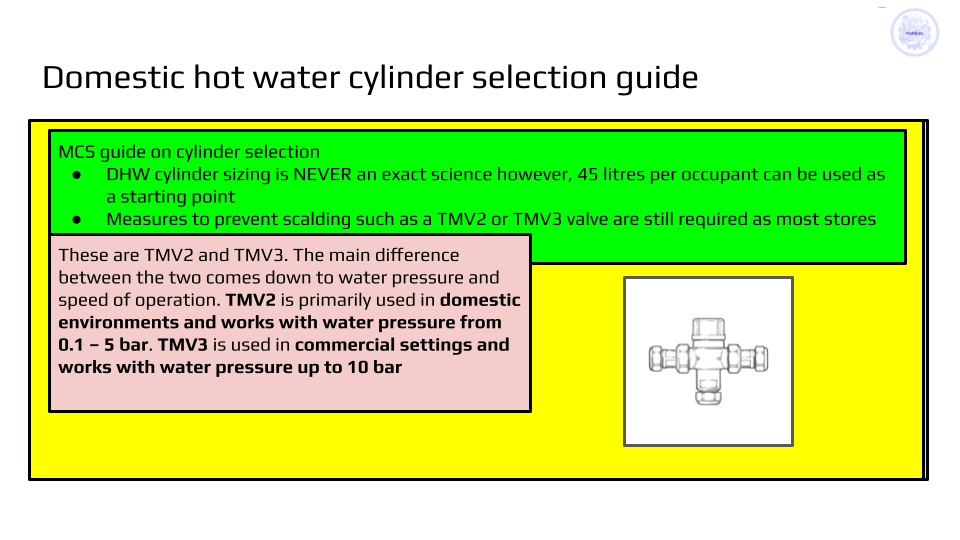

Roles of cylinders and the correct selection of the storage vessel. (Knowledge Task – Behaviour Combined Task) Kt and BCt

Pasteurisation and the considerations along with how it is achieved. (Knowledge Task – Behaviour Combined Task) Kt and BCt

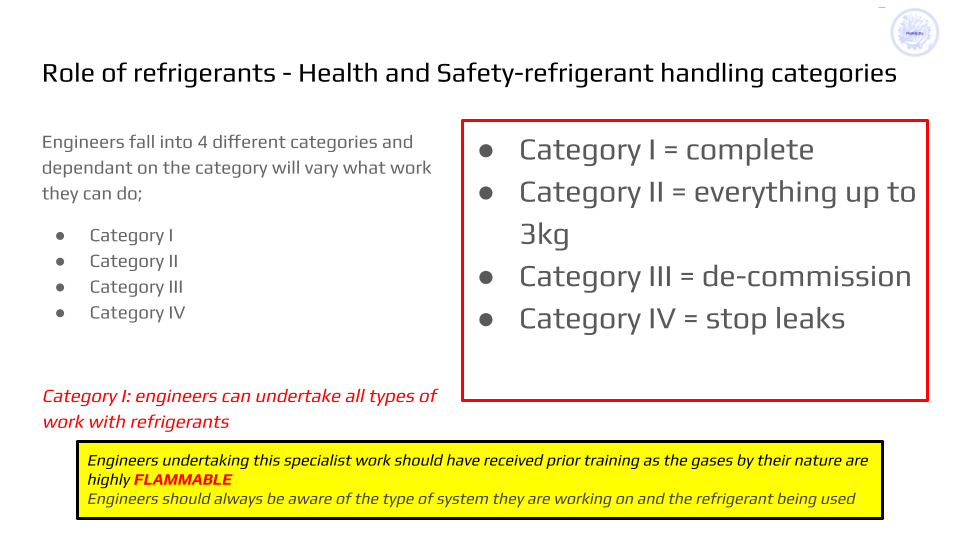

Outlining the importance of the refrigerants, the safe identification and the cycle of the refrigerants along with the flammability and recycle processes. (Knowledge Task – Behaviour Combined Task) Kt and BCt

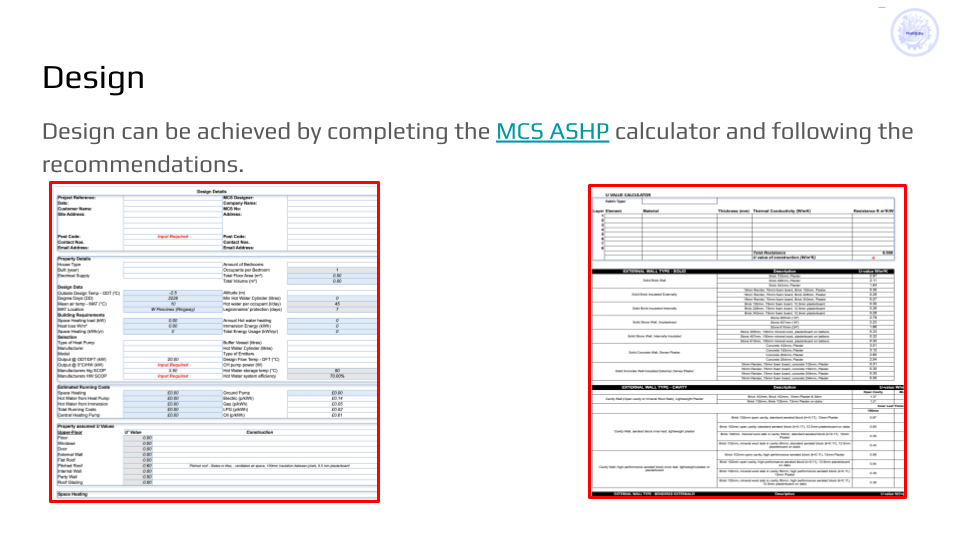

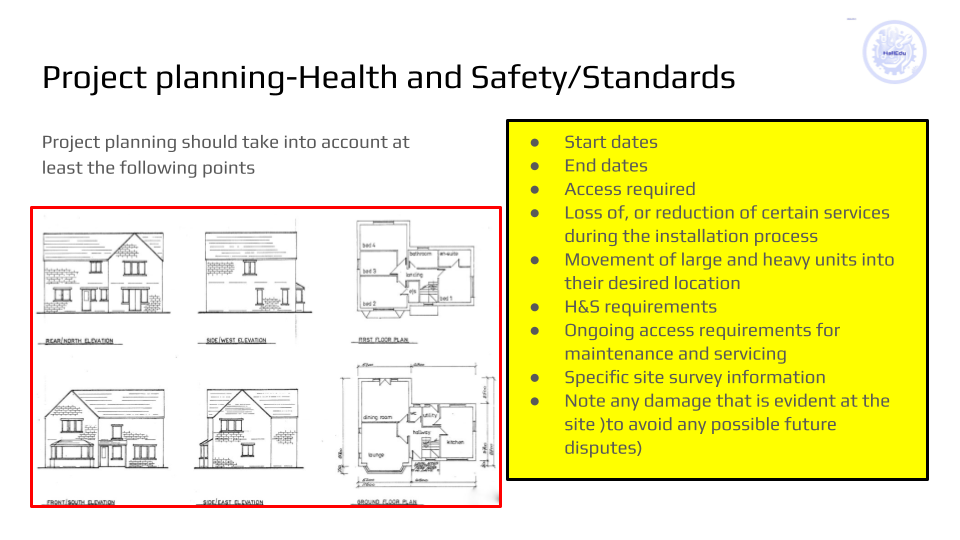

Basic design tasks help further develop critical thinking and planning. These are essential for installation and pre-installation checks. This prepares for installing low temperature heating and hot water systems. (Knowledge Task – Behaviour Combined Task) Kt and BCt

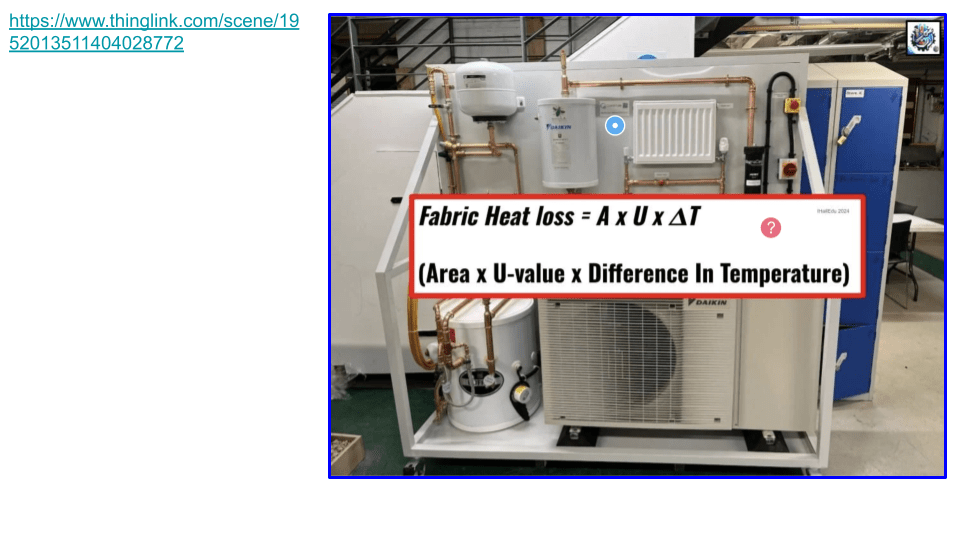

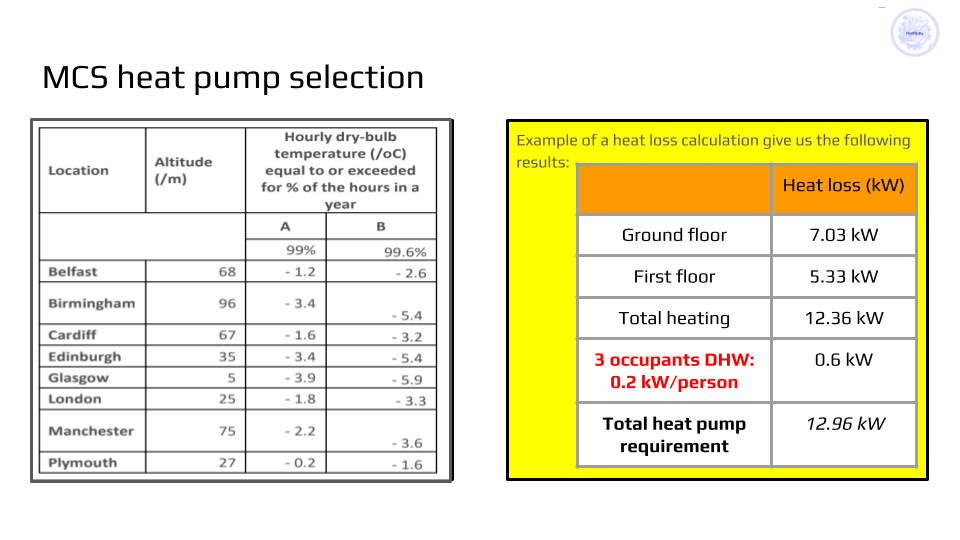

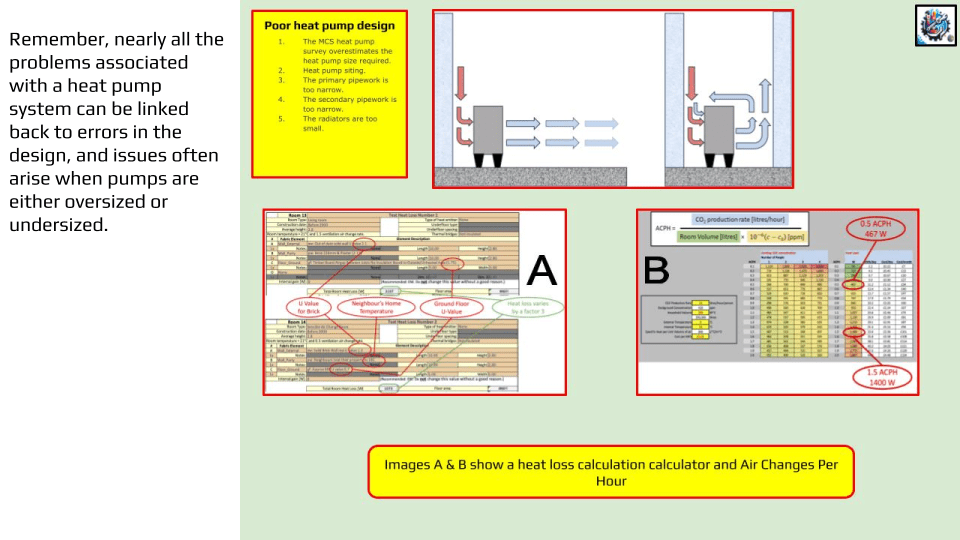

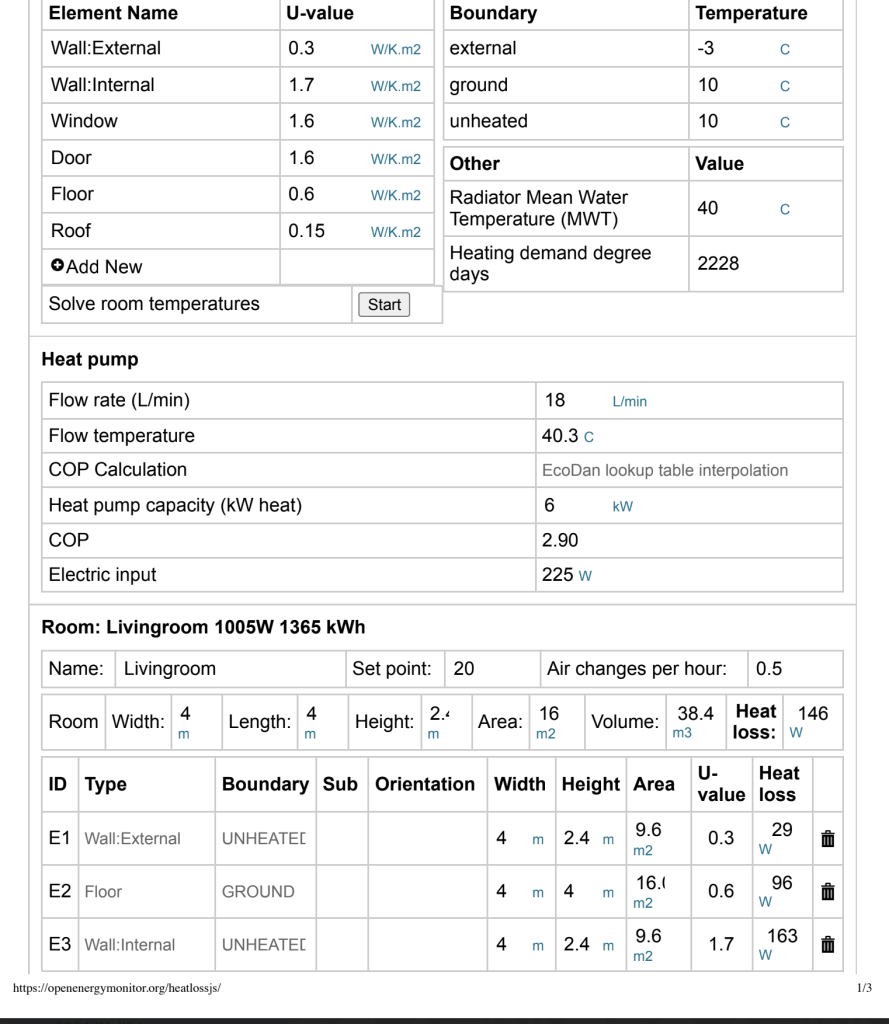

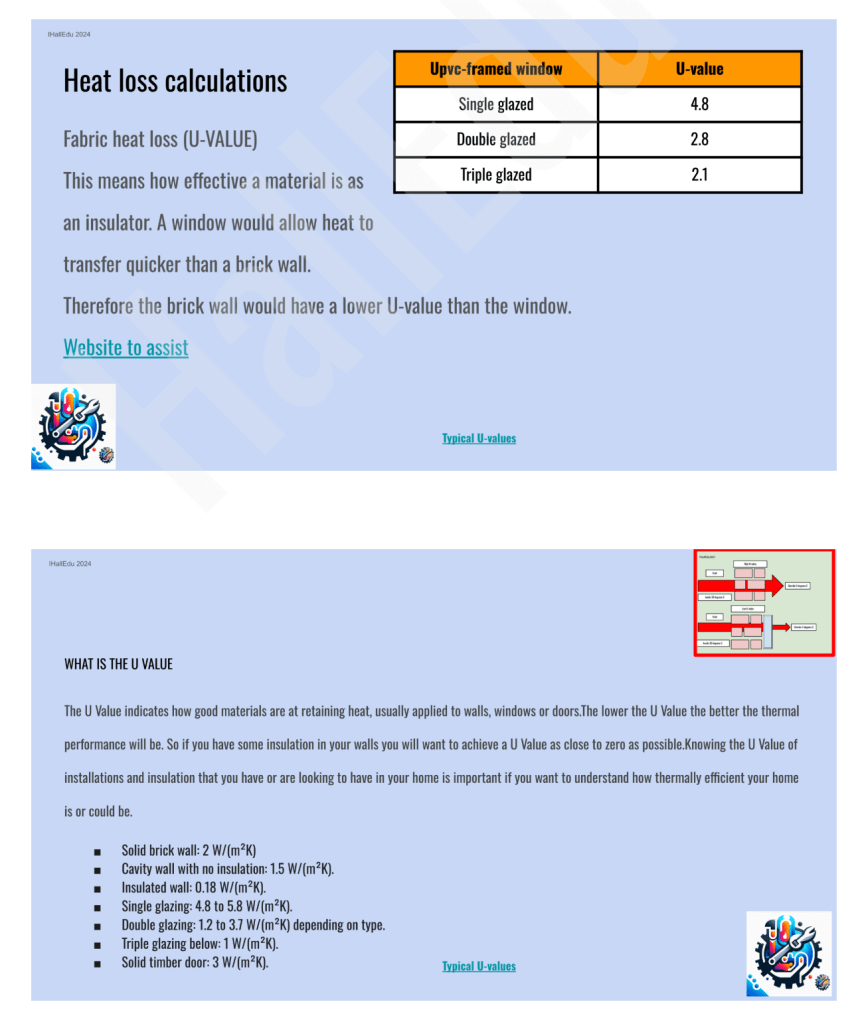

Heat loss/transfer and the appropriate documentation to use and complete when planning to and after installation of the systems. (Knowledge Task – Behaviour Combined Task) Kt and BCt

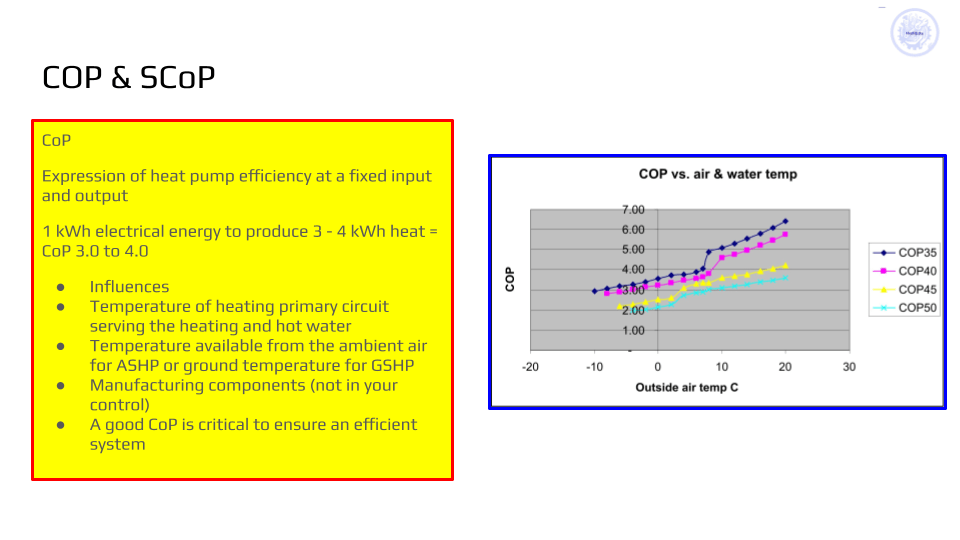

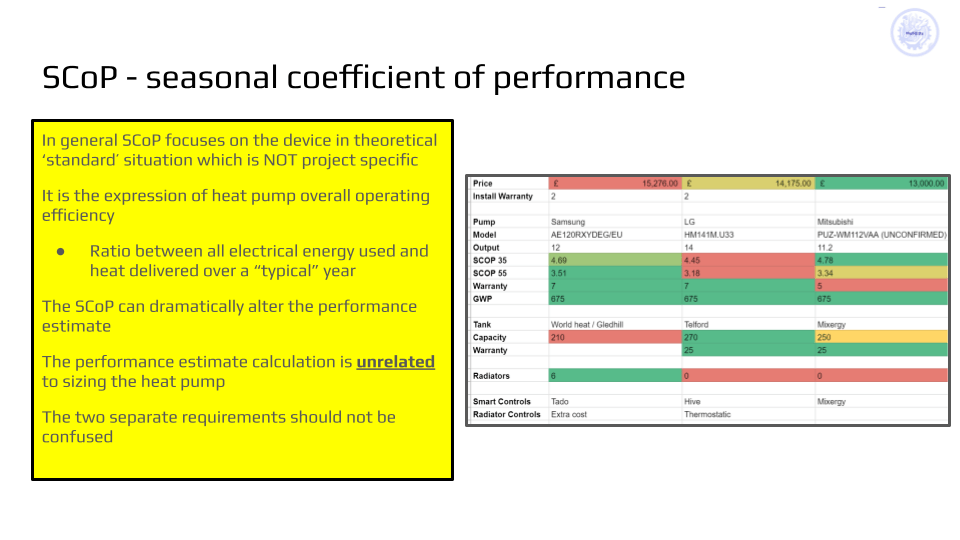

CoP and SCoP, use planning information and manufacturers data. They compare the different outcomes to show to the client. This process aims to offer and support their decision making in the selection of the systems and units available from manufacturers. (Knowledge Task – Behaviour Combined Task) Kt and BCt

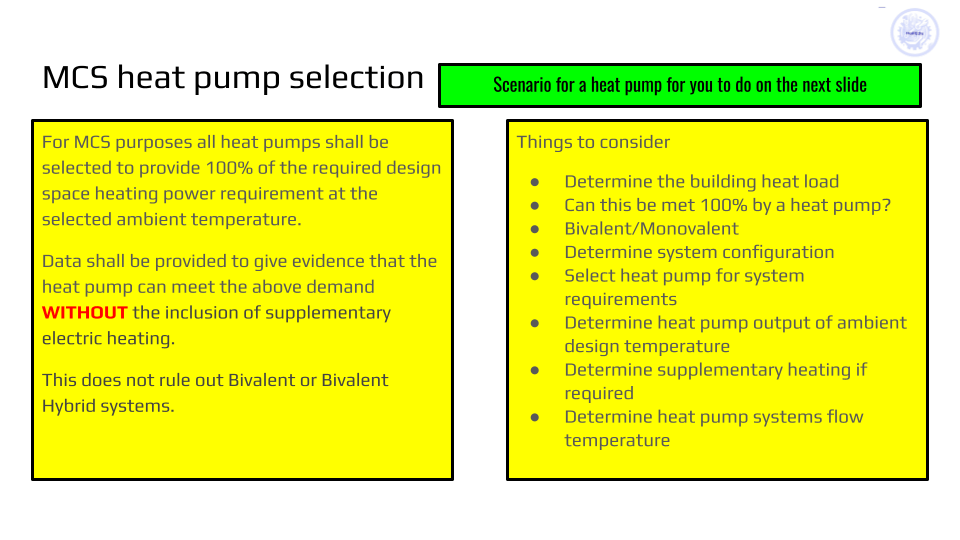

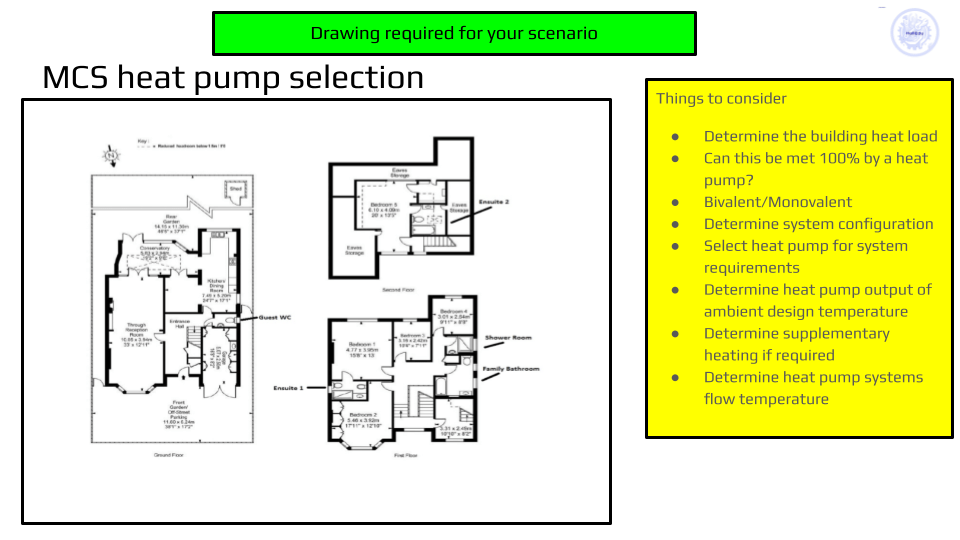

Heat pump sizing, determining the heating load, hot water requirements, and the client’s preferences are essential. Calculations bring all of the data together. These steps are necessary to satisfy the client and the authorities. (Knowledge Task – Behaviour Combined Task) Kt and BCt

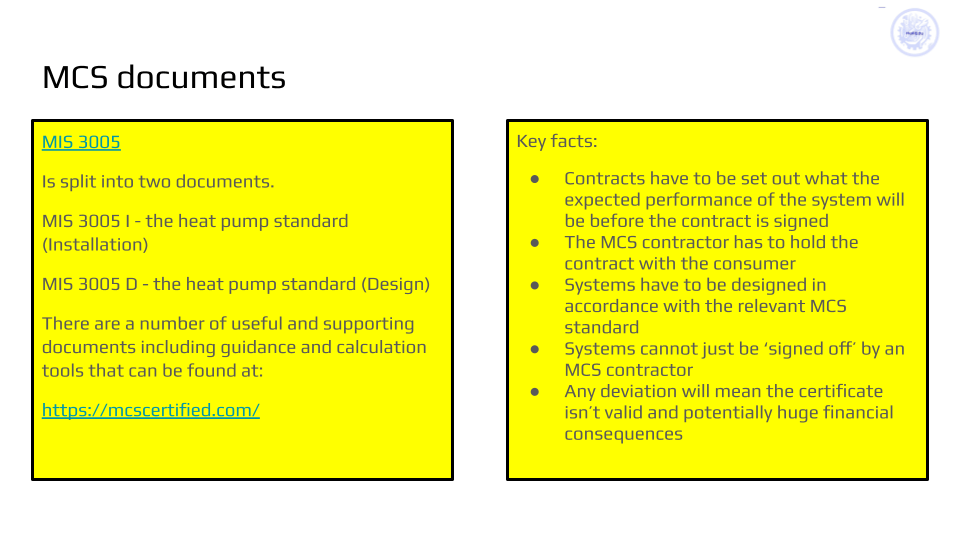

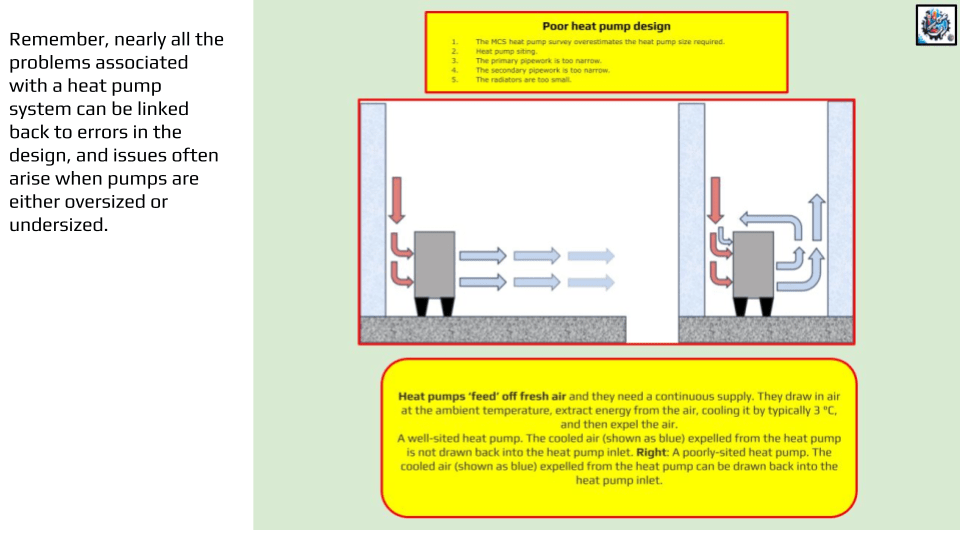

Site location, involves consideration on where to locate the Outside unit. It also involves why and how to locate it in accordance with MCS. This should be aligned with manufacturers literature and client discussions. (Knowledge Task – Behaviour Combined Task) Kt and BCt

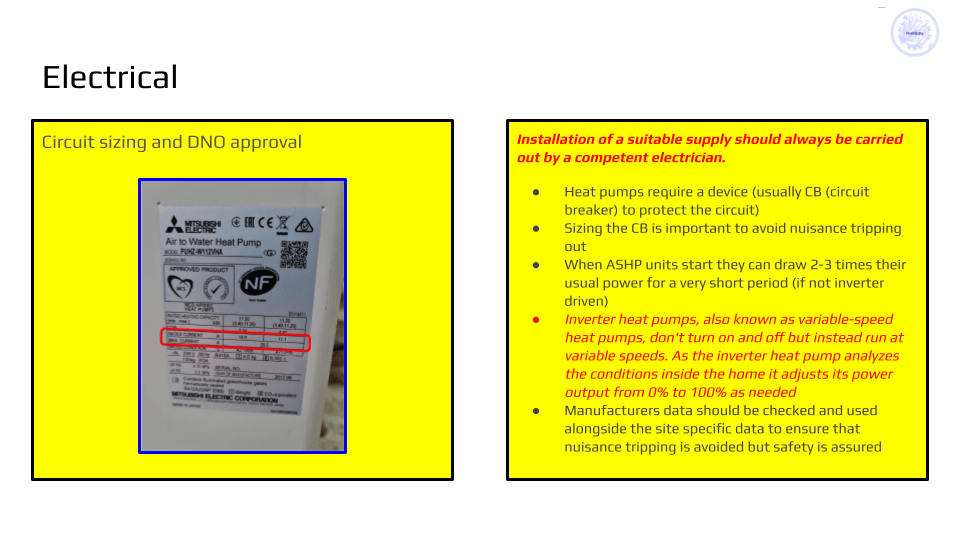

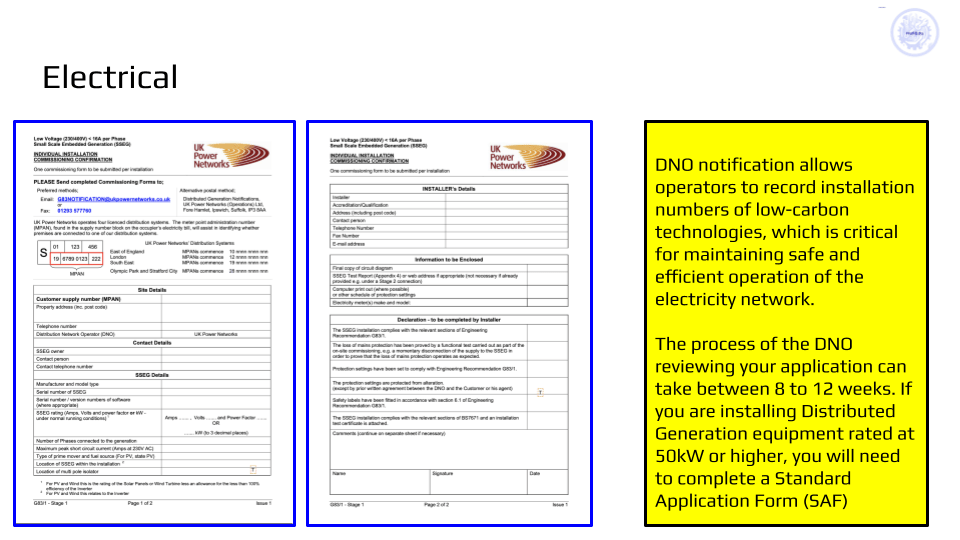

Electrical connection, covering circuit sizing, DNO approval, communication with trades and authorities. (Knowledge Task – Behaviour Combined Task) Kt and BCt

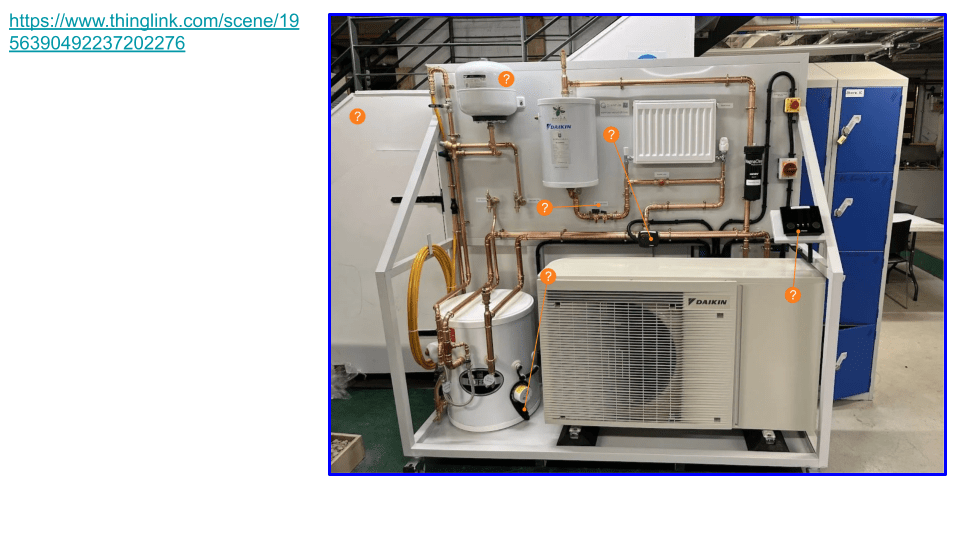

Components, outlining, identifying and recognition of the items that are in the unit. Understanding how they operate with each other allows the system to function. (Knowledge Task – Behaviour Combined Task) Kt and BCt

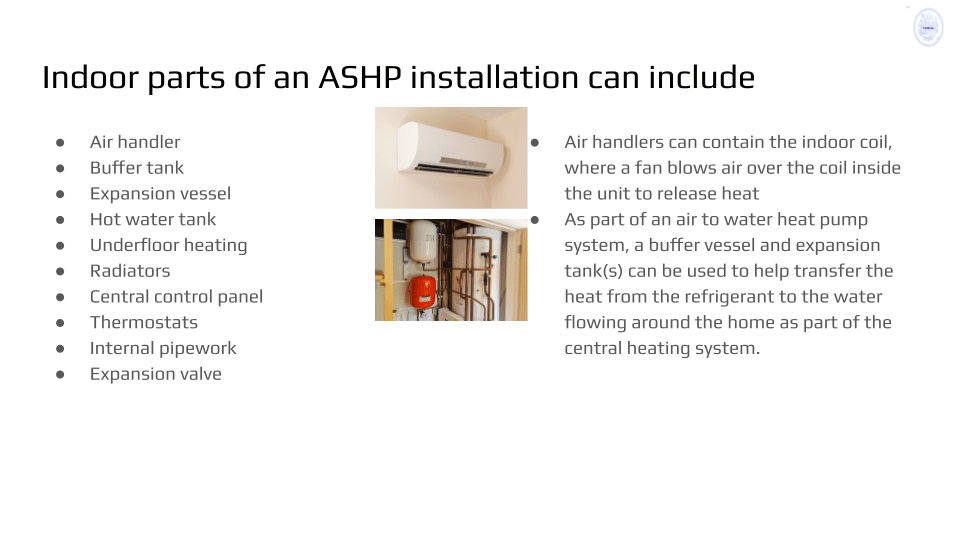

System components. They include the property components and their function and role. They also detail what they all link to and where the data can be found. This provides guidance for the client and the engineer. (Knowledge Task – Behaviour Combined Task) Kt and BCt

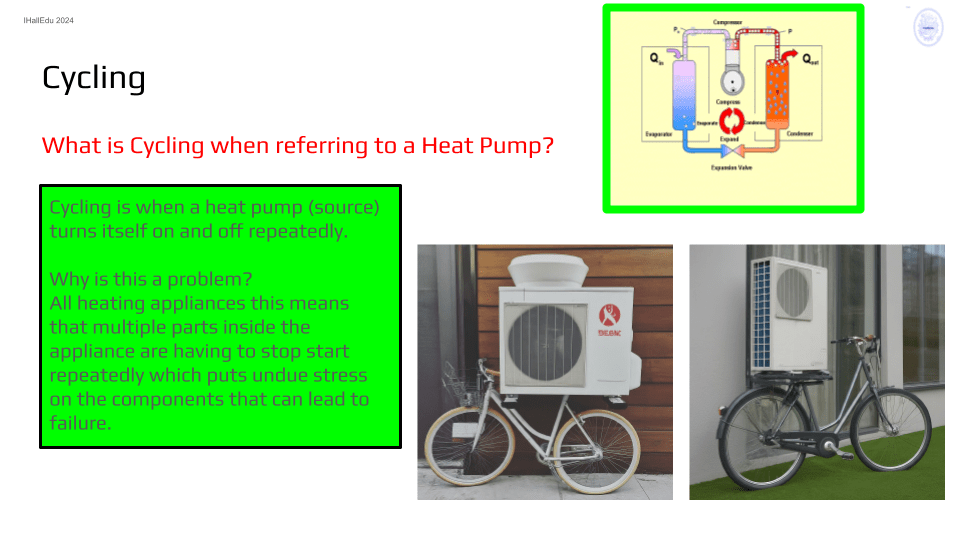

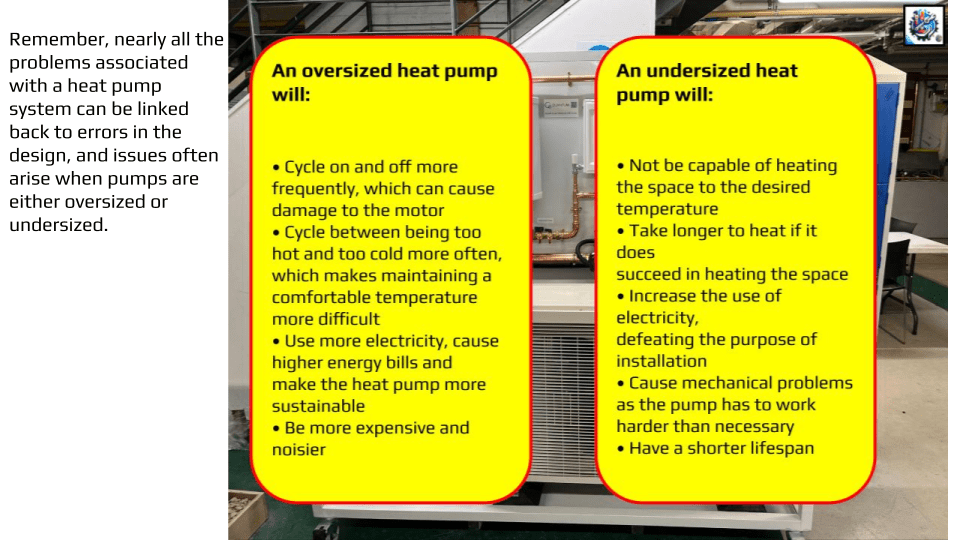

The oversizing problem, linking with the sizing of the heat pump unit. We need to examine the impact of oversizing. It is important to understand why it is occurring. We must consider the remedies post and pre installation to overcome the issues. (Knowledge Task – Behaviour Combined Task) Kt and BCt

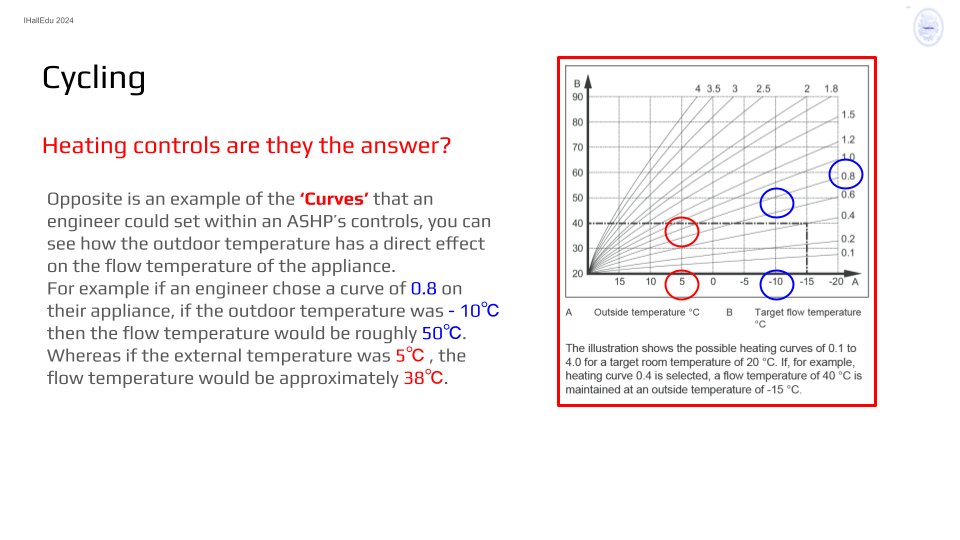

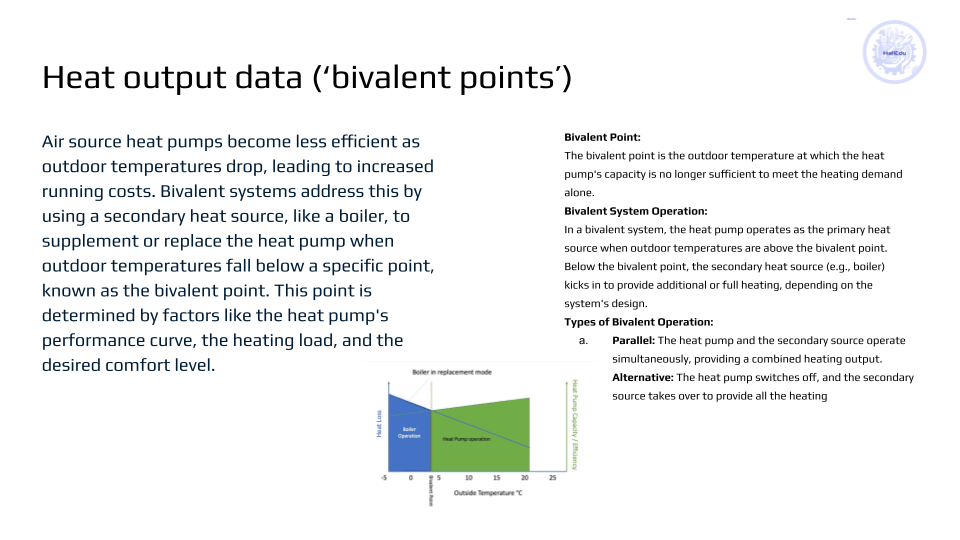

Heat curves, what they are, how to set them up and what impact on the system they have. (Knowledge Task – Behaviour Combined Task) Kt and BCt

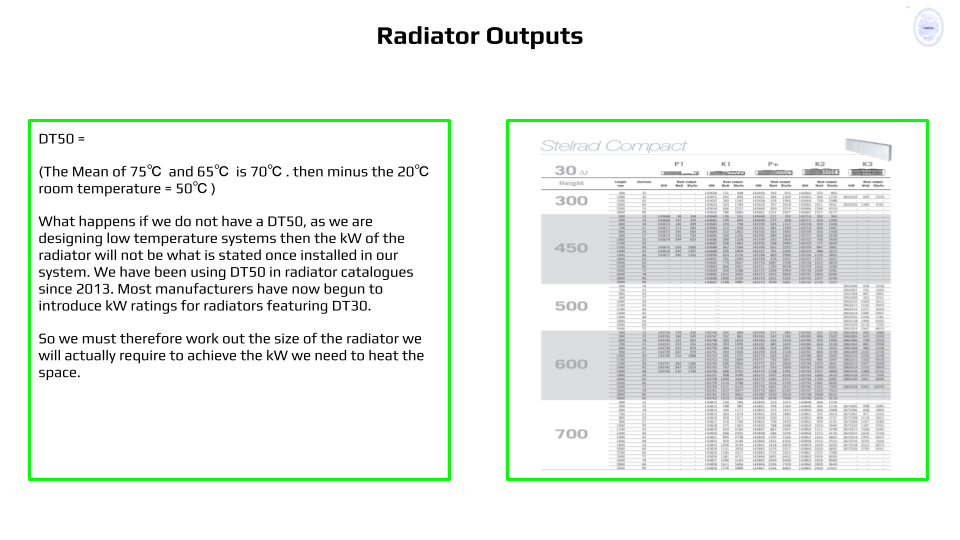

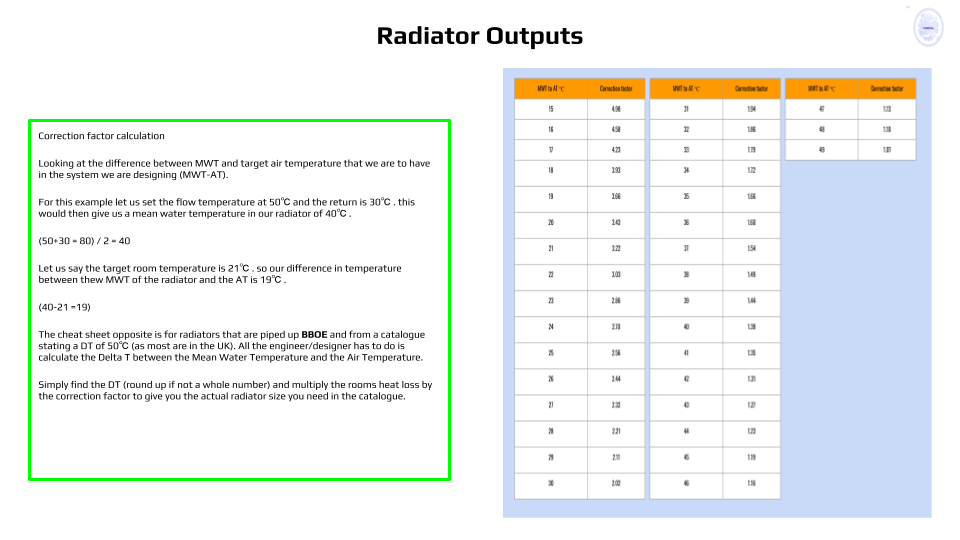

Heat emitter sizing, design factors, and temperatures must be considered. This is important when discussing and deciding how to meet the design temperatures for the system. Discovering the benefits of hydraulic separation and how to factor this into the system design and installation. (Knowledge Task – Behaviour Combined Task) Kt and BCt

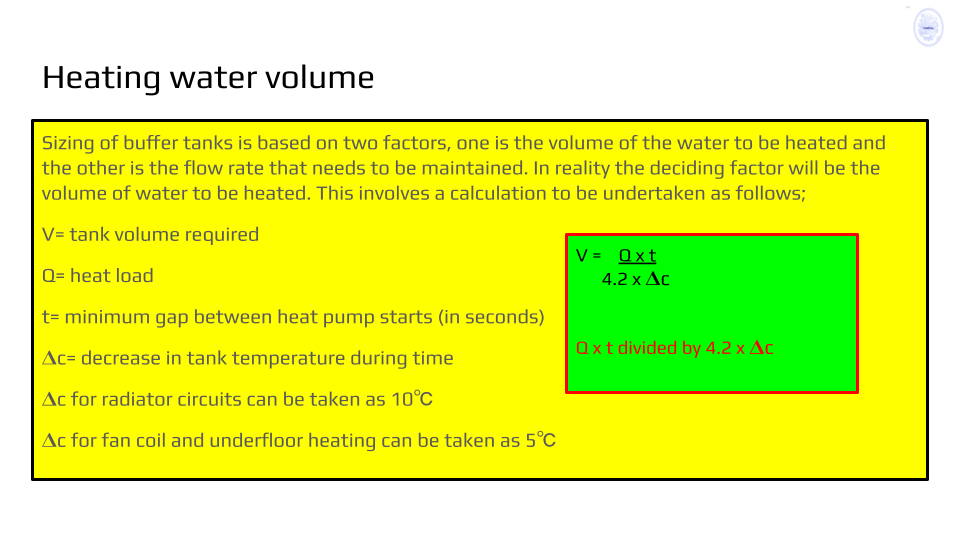

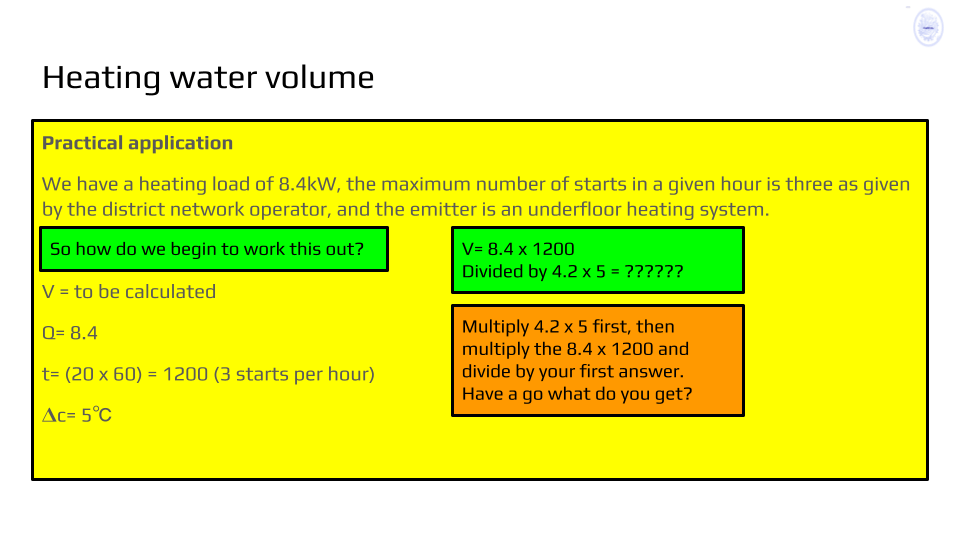

Heating water volume, what is it, how do we calculate it? What do we do with this information when we have it? (Knowledge Task – Behaviour Combined Task) Kt and BCt

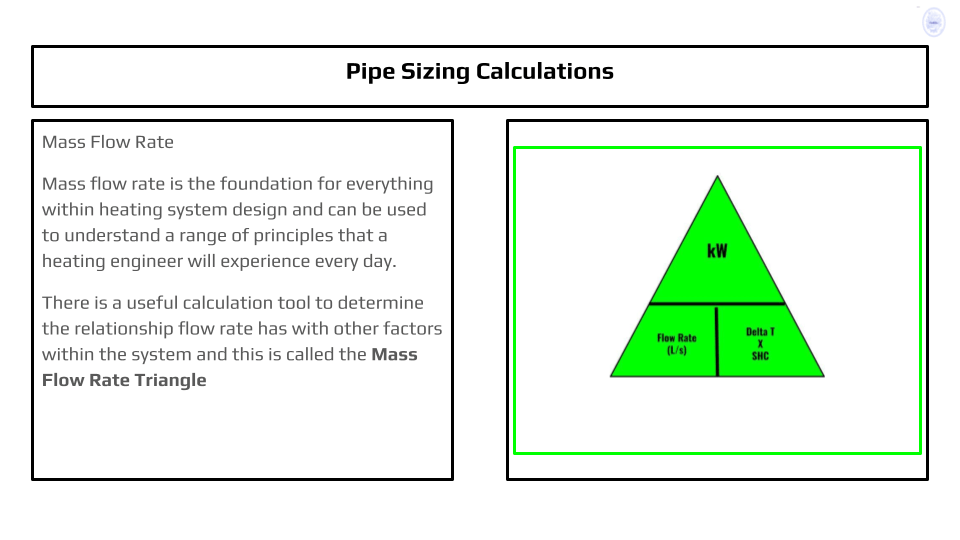

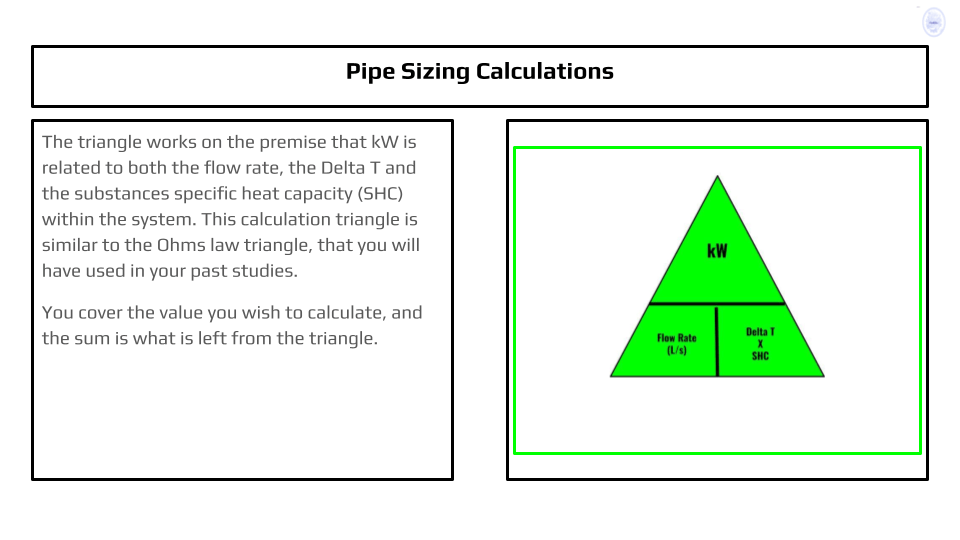

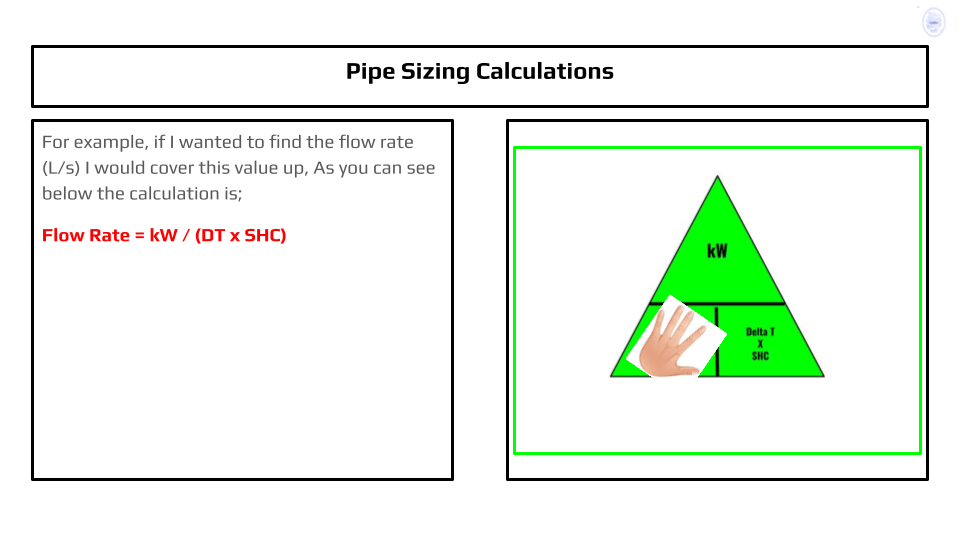

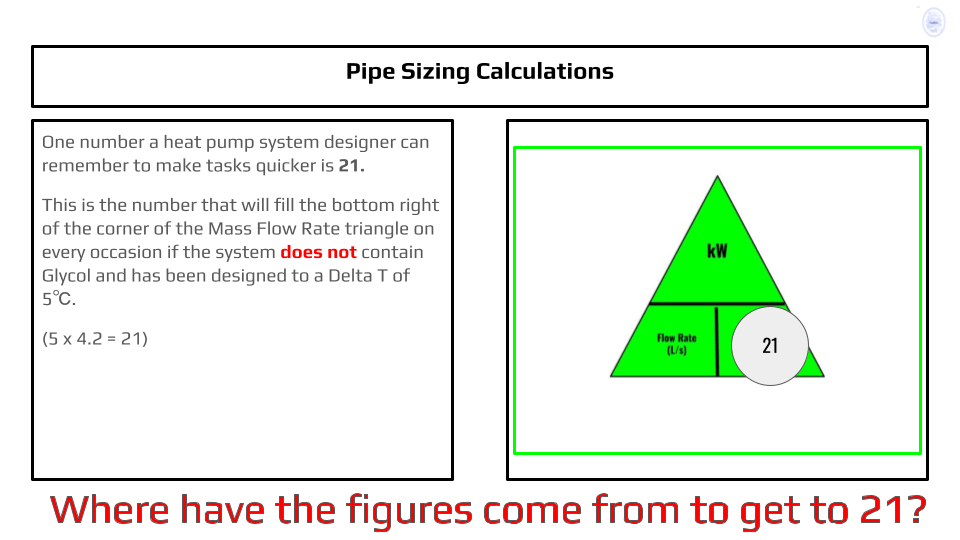

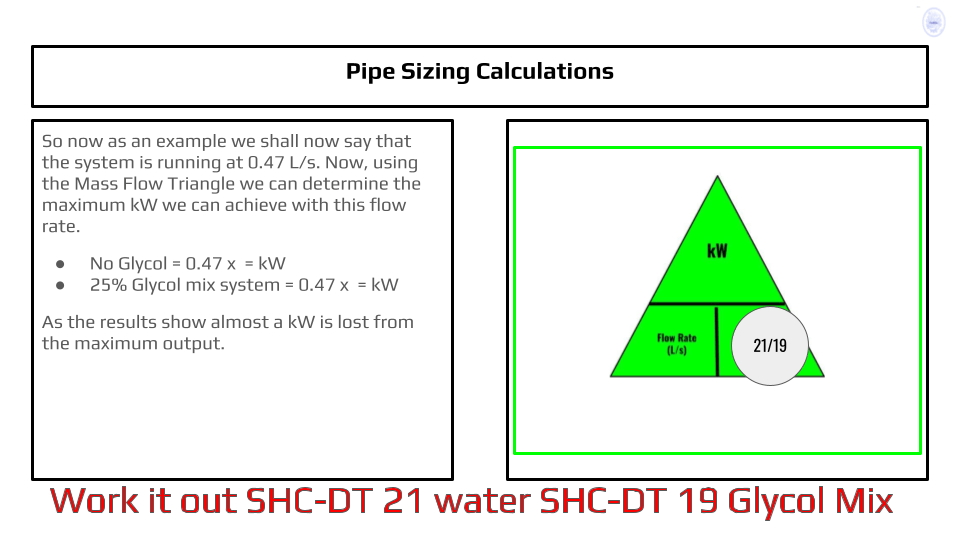

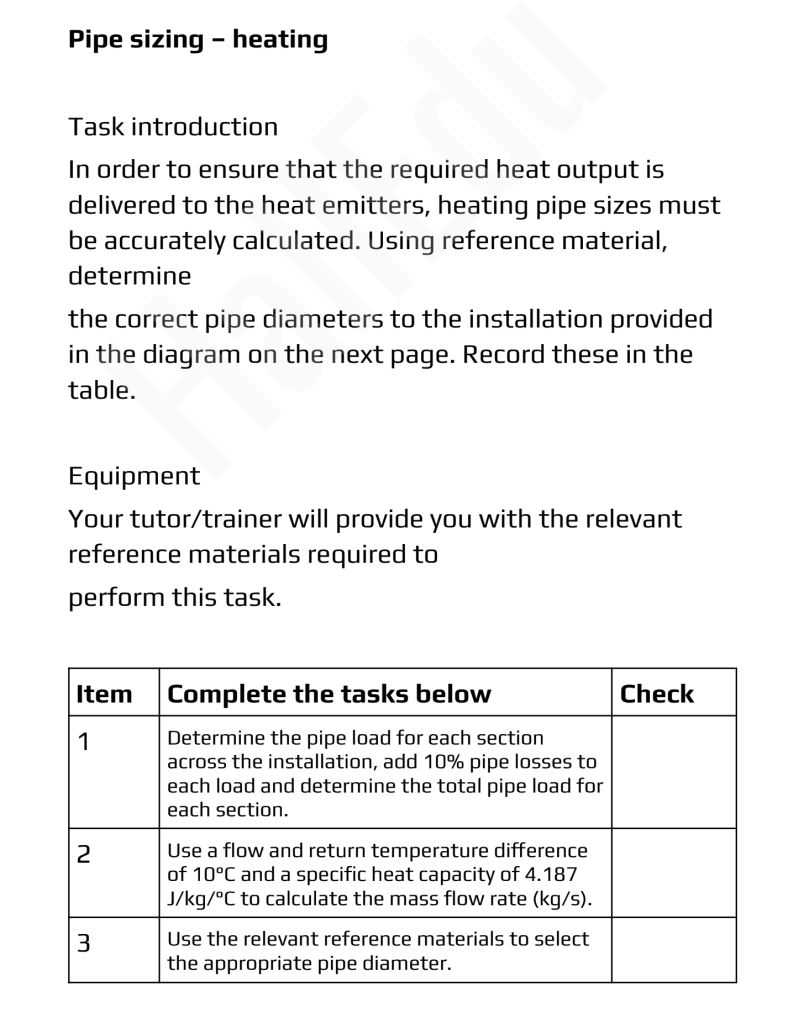

Pipe sizing calculation, How do we ensure the pipework conveys the correct amount of energy? This energy is necessary to furnish the system. It allows the emitters to achieve the design temperatures throughout the system. What options are available, when water or Glycol is being used? (Knowledge Task – Behaviour Combined Task) Kt and BCt

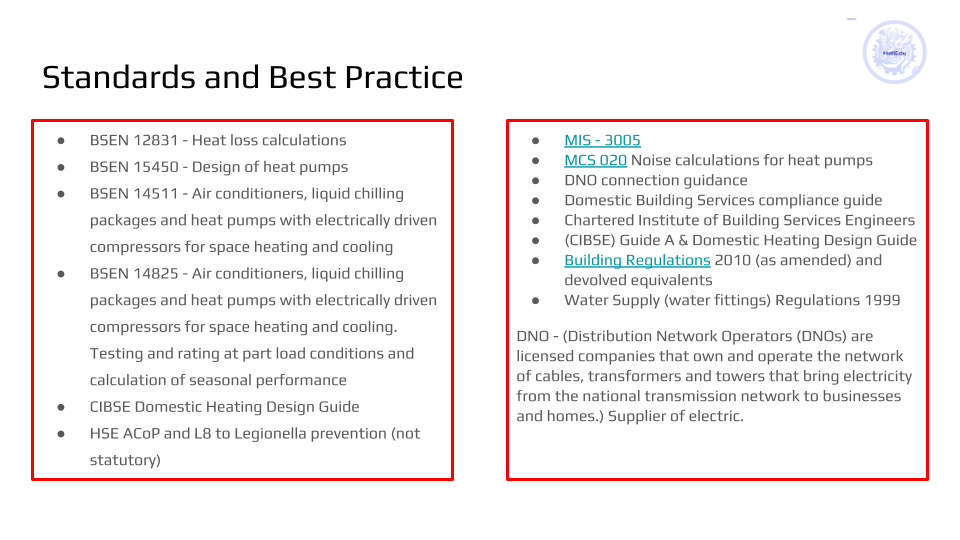

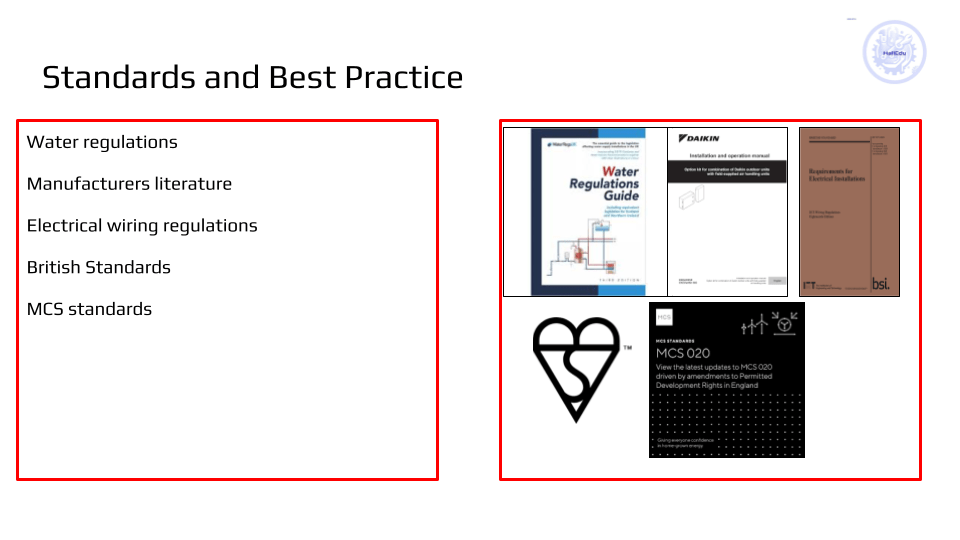

Standards, the appropriate standards required for the industry exercise are completed in all areas of year 2. The correct documentation informs and guides the apprentices. (Knowledge Task – Behaviour Combined Task) Kt and BCt

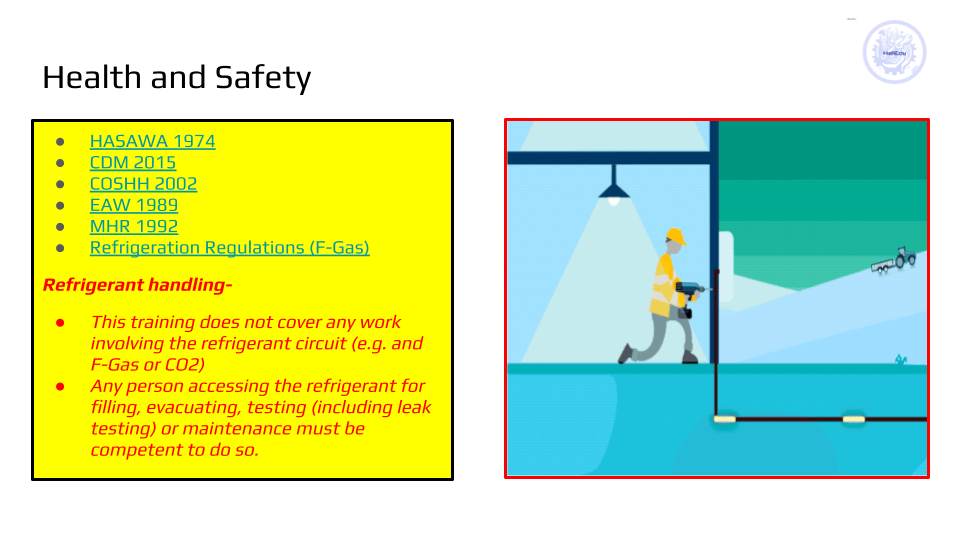

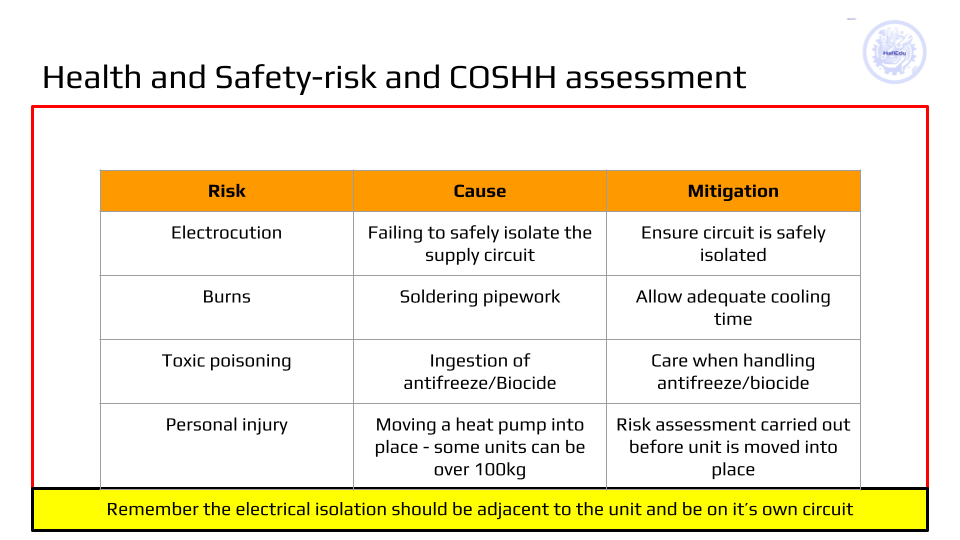

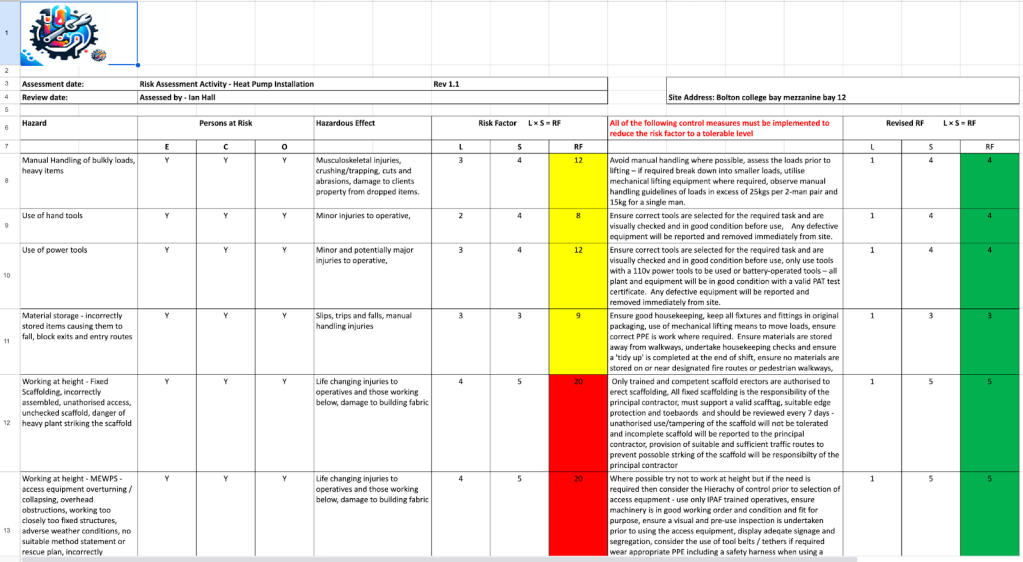

Safe working practices, this is covered holistically throughout the training plan of the apprenticeship. However, the apprentices are consistently advised. They are guided to the safe working documentation for their activities. (Knowledge Task – Behaviour Combined Task) Kt and BCt

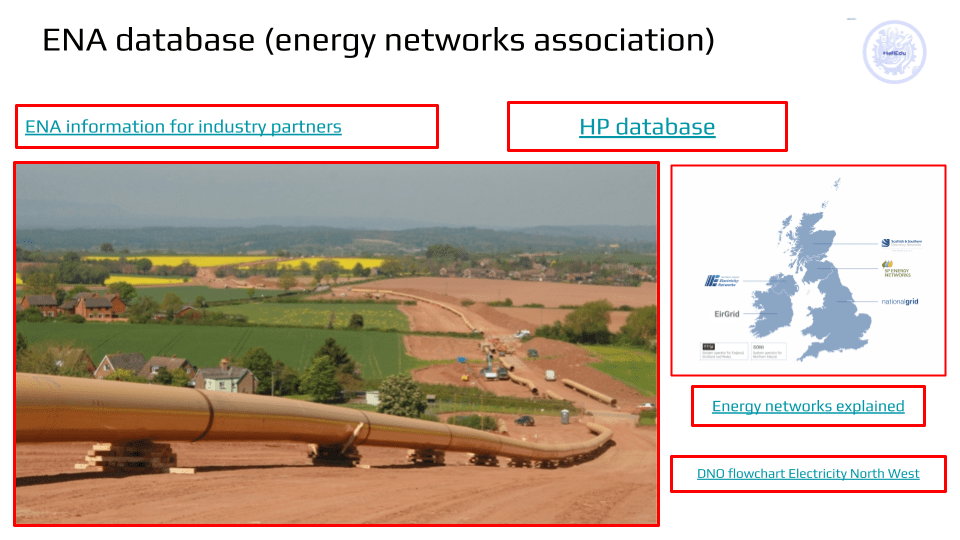

ENA database, commissioning and verification of the installation, (Knowledge Task – Behaviour Combined Task) Kt and BCt

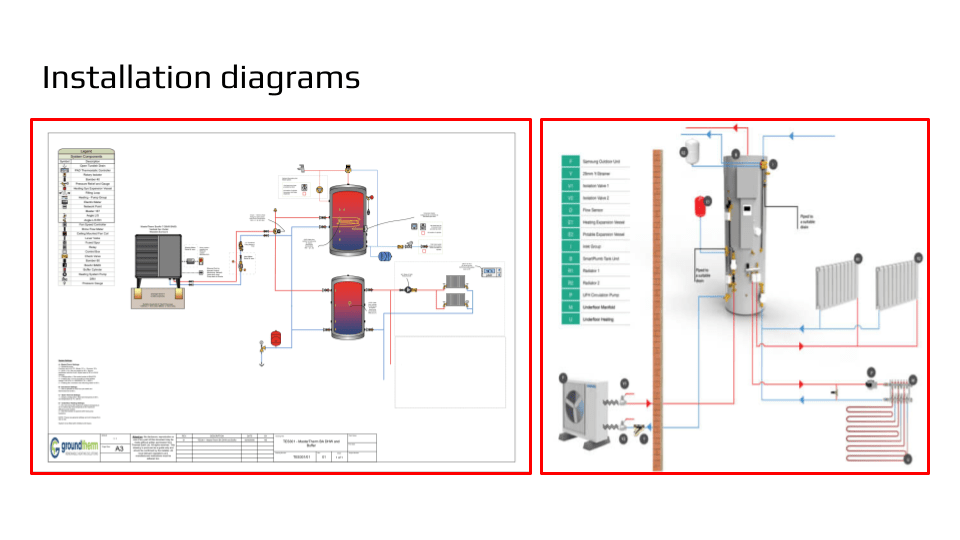

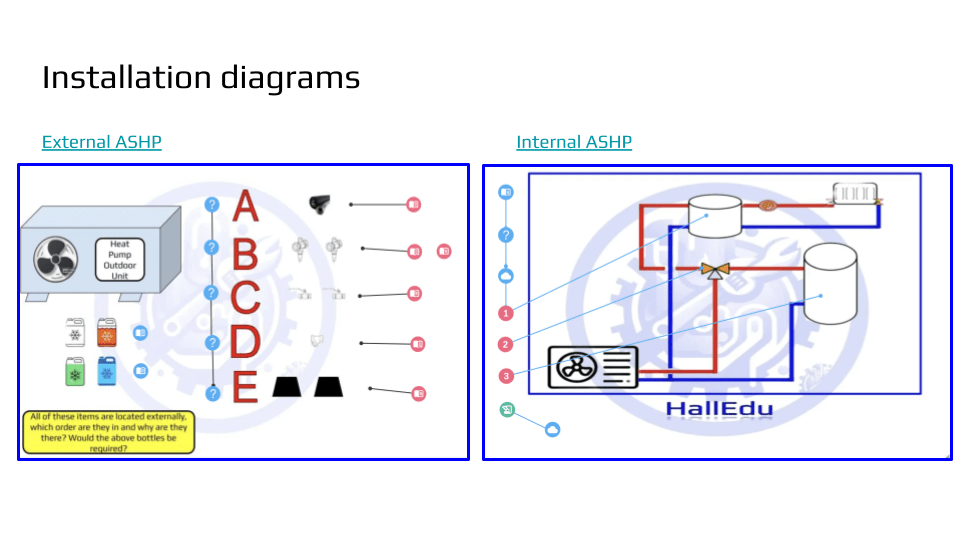

Installation plans and designs, learning to interpret and create installation diagrams, from plans and manufacturers literature. (Knowledge Task – Behaviour Combined Task) Kt and BCt

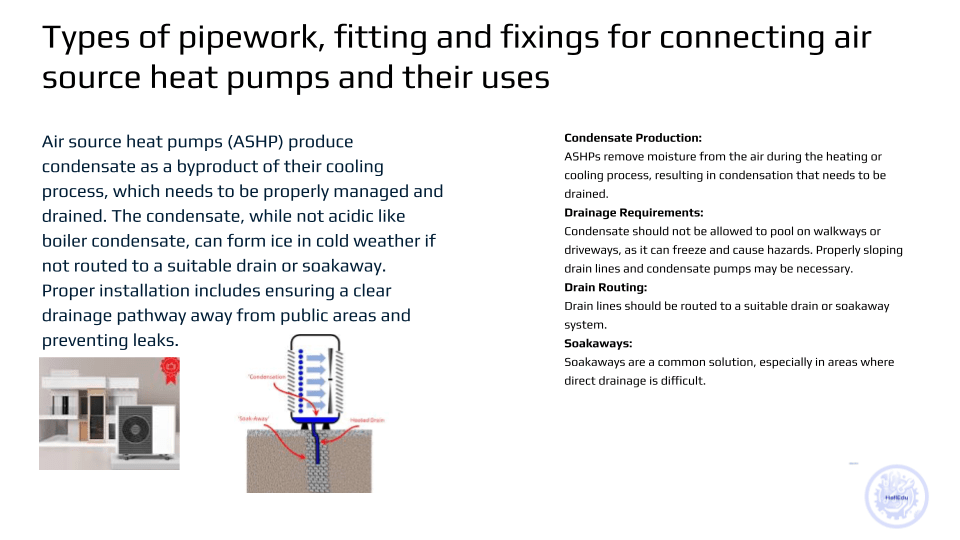

Common installation issues, how they present themselves to the client and how to avoid these mistakes when planning and installing. (Knowledge Task – Behaviour Combined Task) Kt and BCt

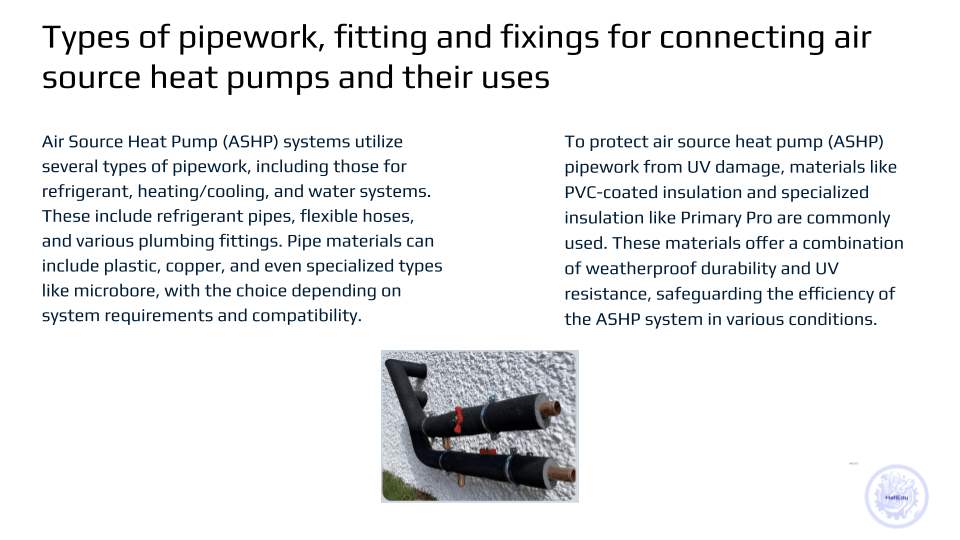

Pipework, fittings and connections, detailing the appropriate pipework. It includes installation methods, jointing methods, and insulation of pipework. These are detailed in appropriate standards and manufacturers literature. (Knowledge Task – Behaviour Combined Task) Kt and BCt

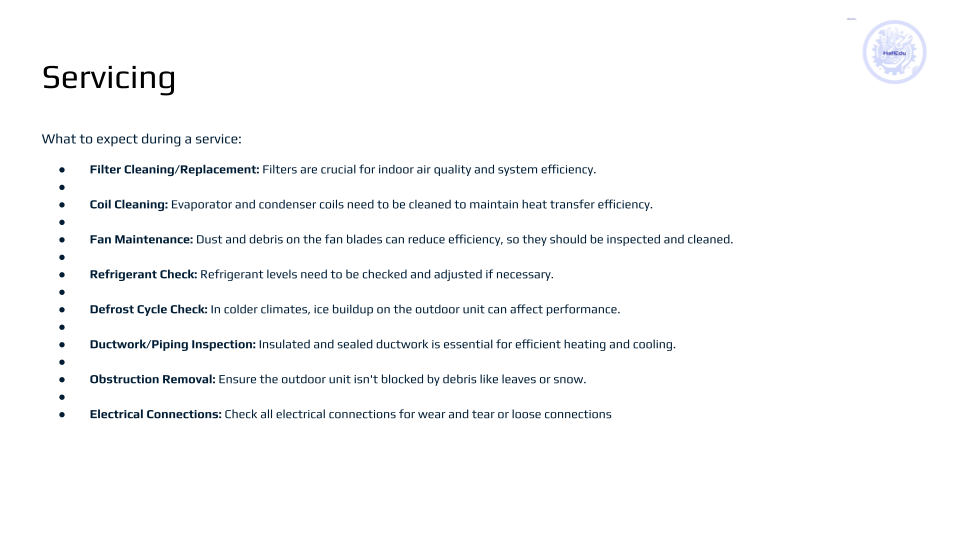

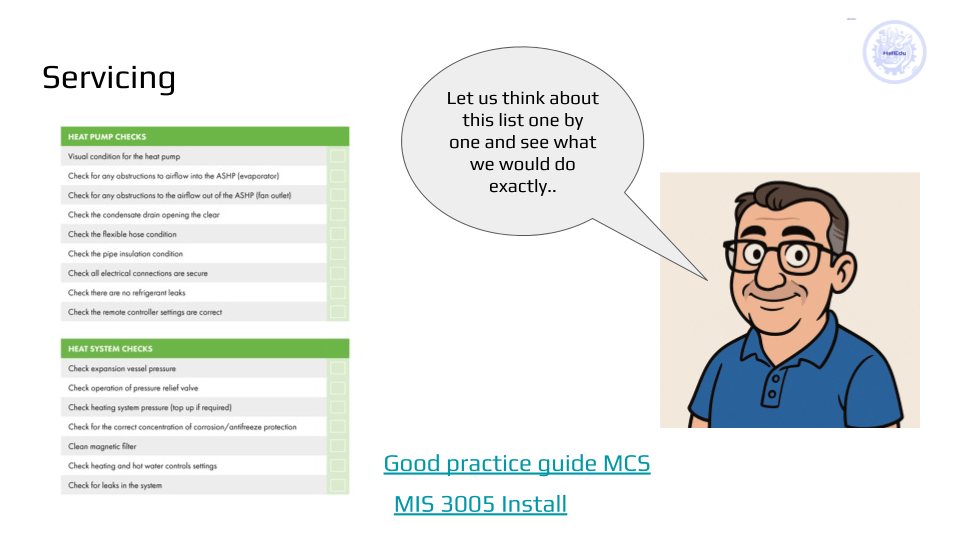

Servicing of ASHP, the correct approach, communication with trades, clients and the identification of issues and rectification. Completion of correct paperwork, reading and interpretation of data and MI’s. (Knowledge Task – Behaviour Combined Task) Kt and BCt

Here is a range of images. Some detail of the items covered in year two of the LCHT apprenticeship standard is also included. All of these are classroom activities. They are taken from the 10 duties of the apprenticeship standard. The KSB’s are also from said standard. I combine these to feature the Kt (knowledge task) and BCt (behaviour combined task). In the pages below, you will see the practical elements. These are carried out in year two of the apprenticeship standard. They are classed as St (skills task) and BCt (behaviour combined task).

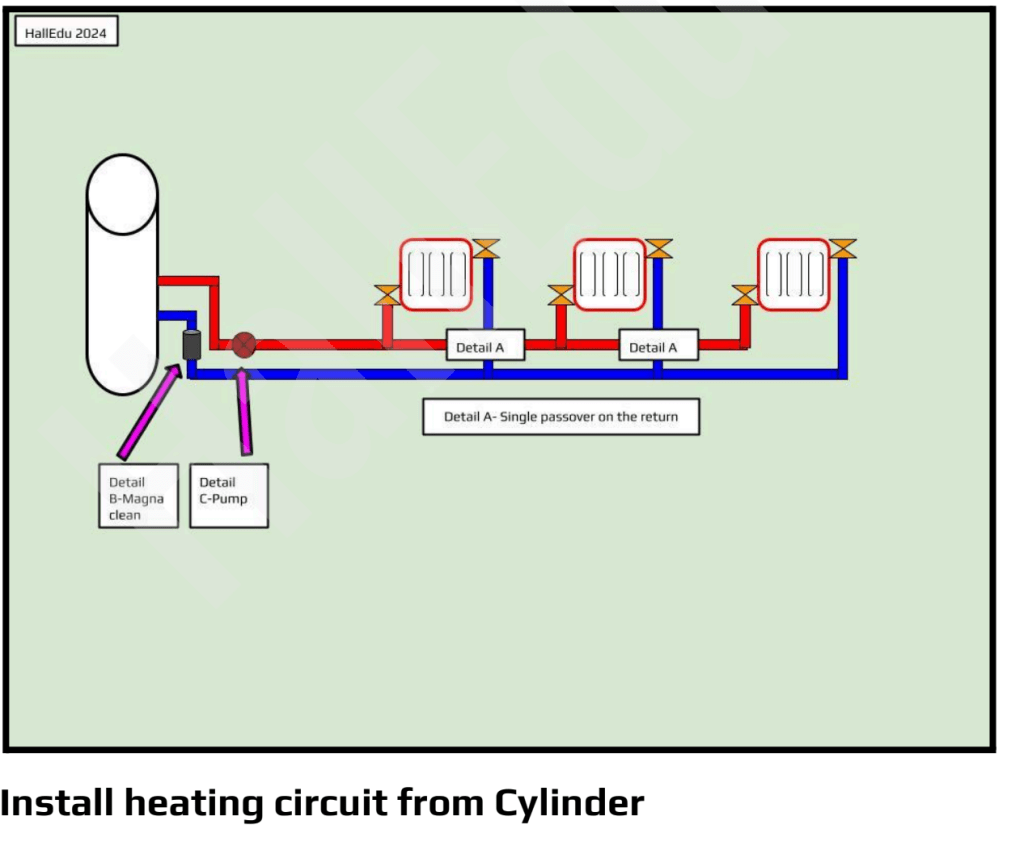

St 1 – Installing heating circuit from cylinder inclusive of sizing, materials list and method statement. (Skills Task – Behaviour Combined Task) St and BCt

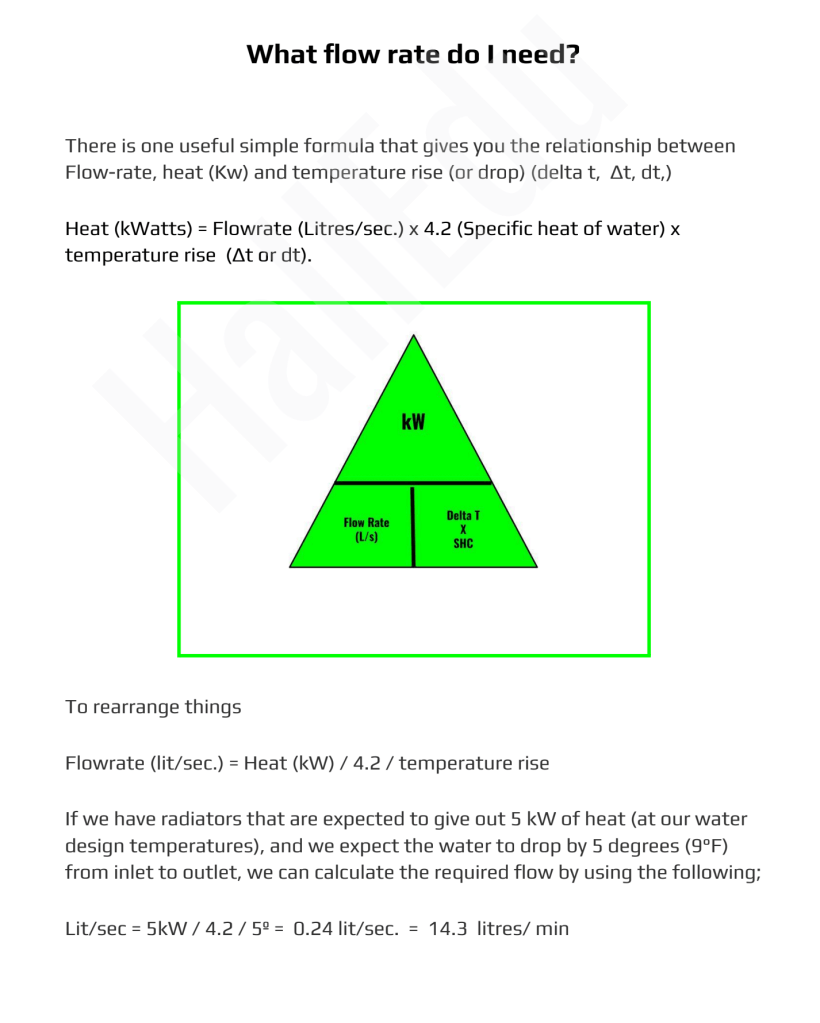

St 2 – Flow rate, what is it? What do I need? Calculating flow rates in the workshop and using MI’s data to assist in selection of pipe sizing.

(Skills Task – Behaviour Combined Task) St and BCt

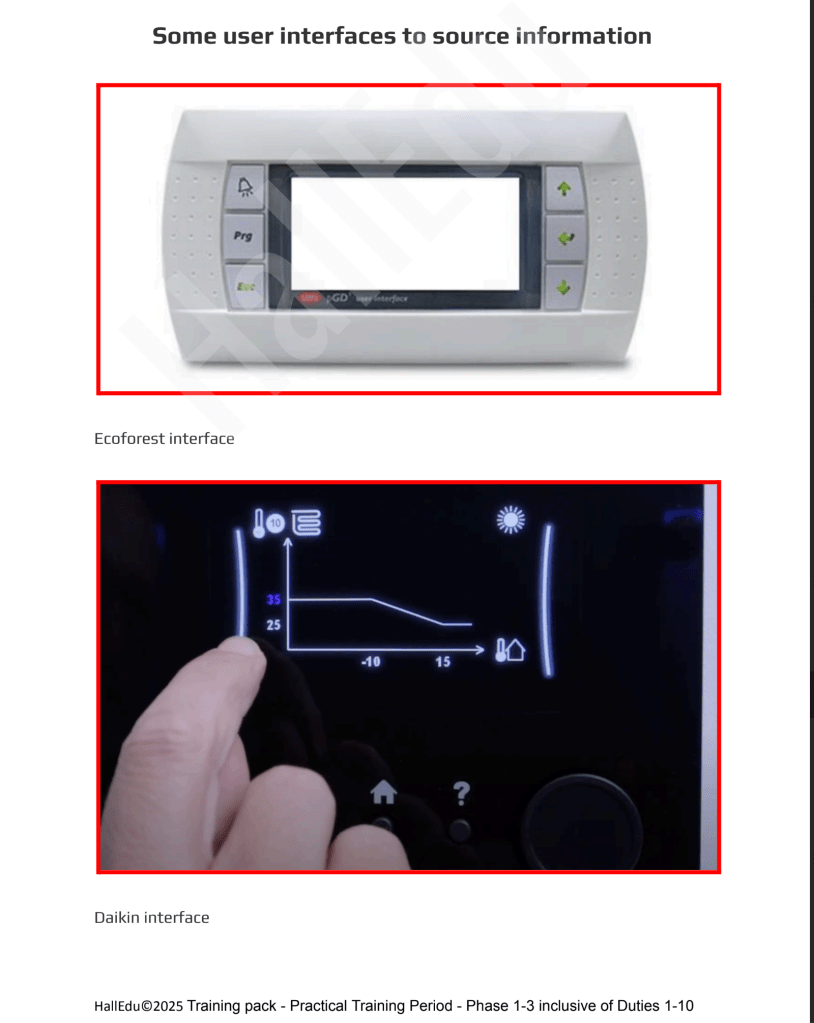

St 3 – User interfaces, tasks of using a range of interfaces from a variety of manufacturers to locate and record data. For example;

Flow rate, outdoor temperature and winter or summer setting

Compressor start ups, Alarm logs – Disinfection program (Skills Task – Behaviour Combined Task) St and BCt

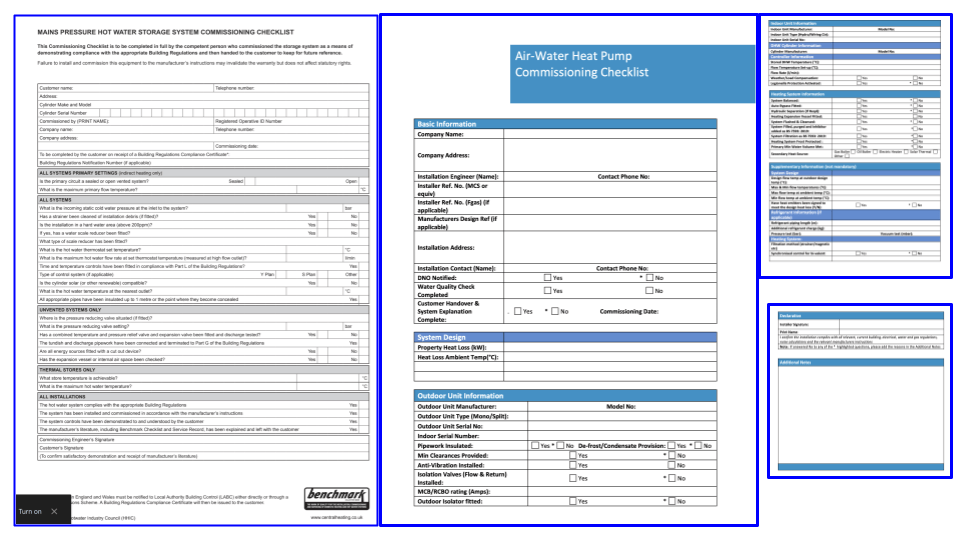

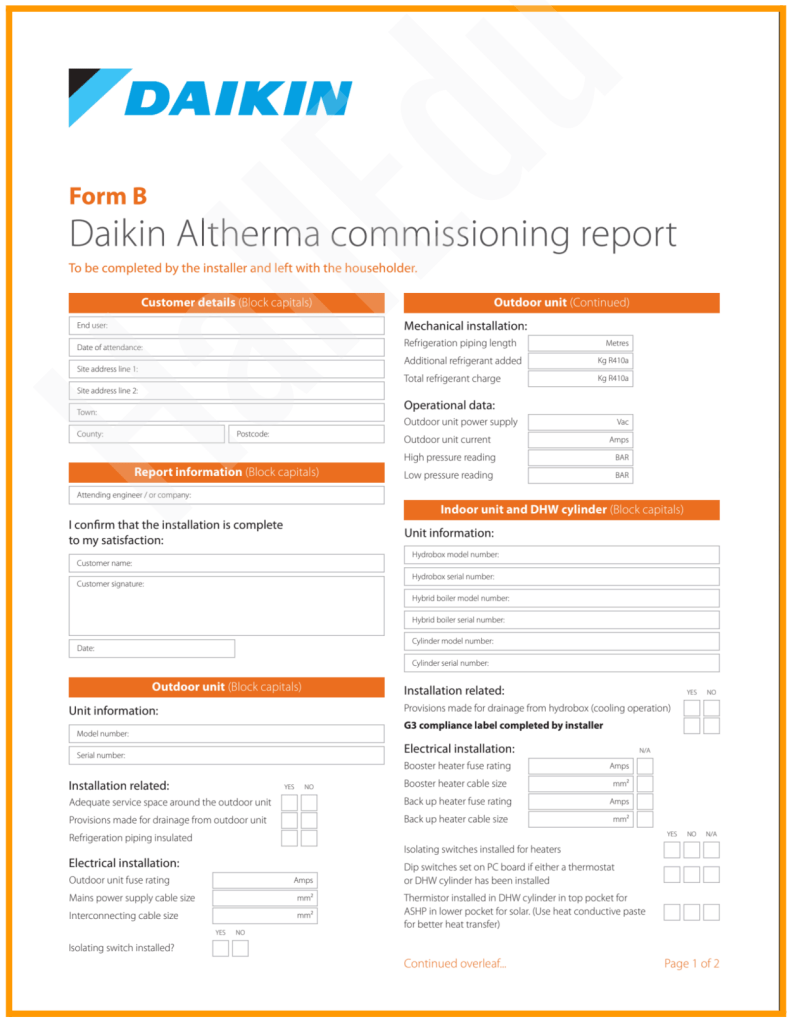

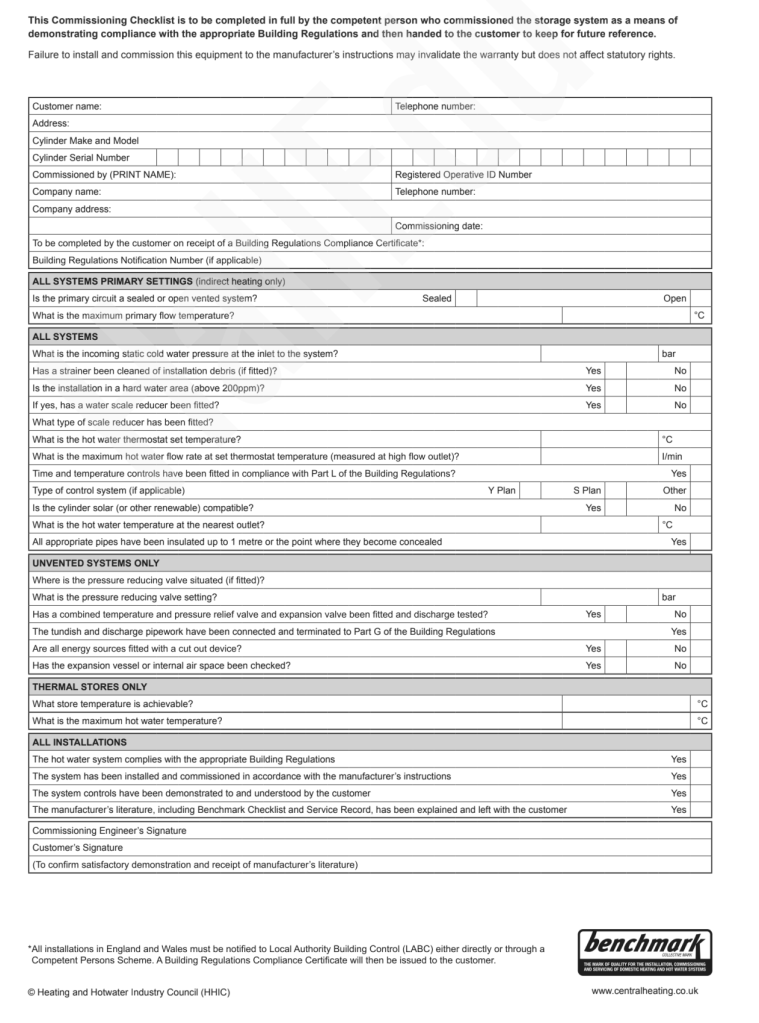

St 4 – Commissioning checklists, working with numerous MI’s and carrying out check lists before start up. (Skills Task – Behaviour Combined Task) St and BCt

St 5 – Complete a range of commissioning reports on various installations from different makes and models. (Skills Task – Behaviour Combined Task) St and BCt

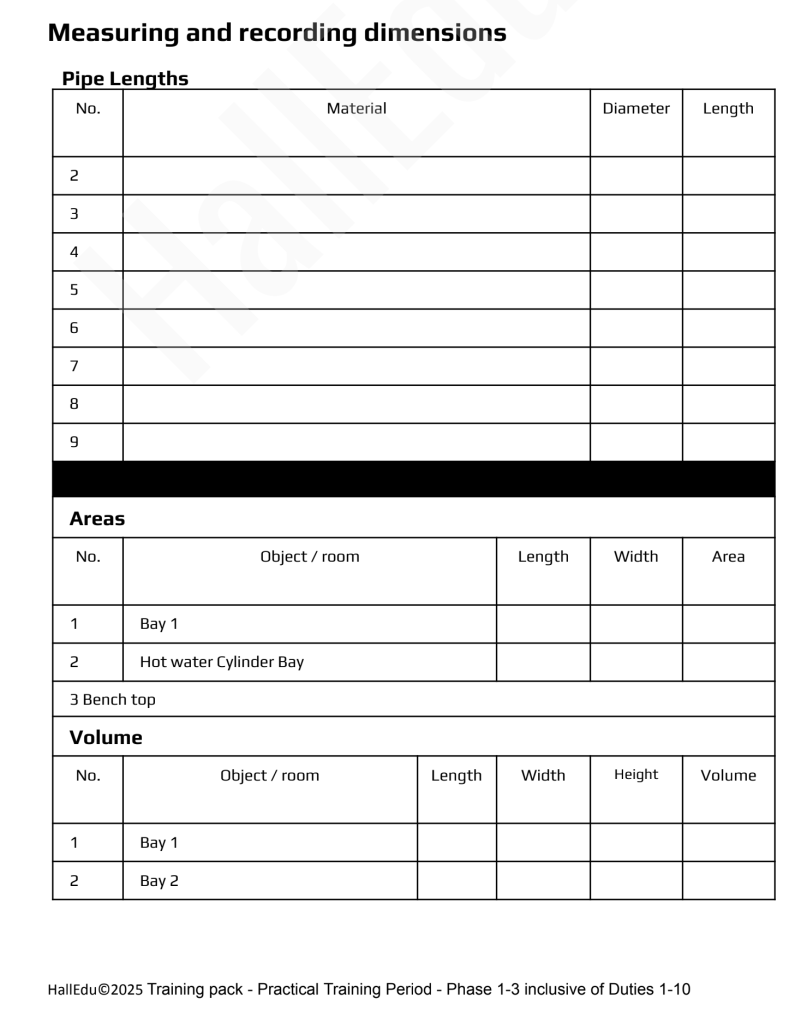

St 6 – Measure and record dimensions. This ensures that the inputting of data into calculations is accurate and in the correct format. (Skills Task – Behaviour Combined Task) St and BCt

St 7 – Working with technology to measure and record levels, inputting to online calculators and hard copy calculations. (Skills Task – Behaviour Combined Task) St and BCt

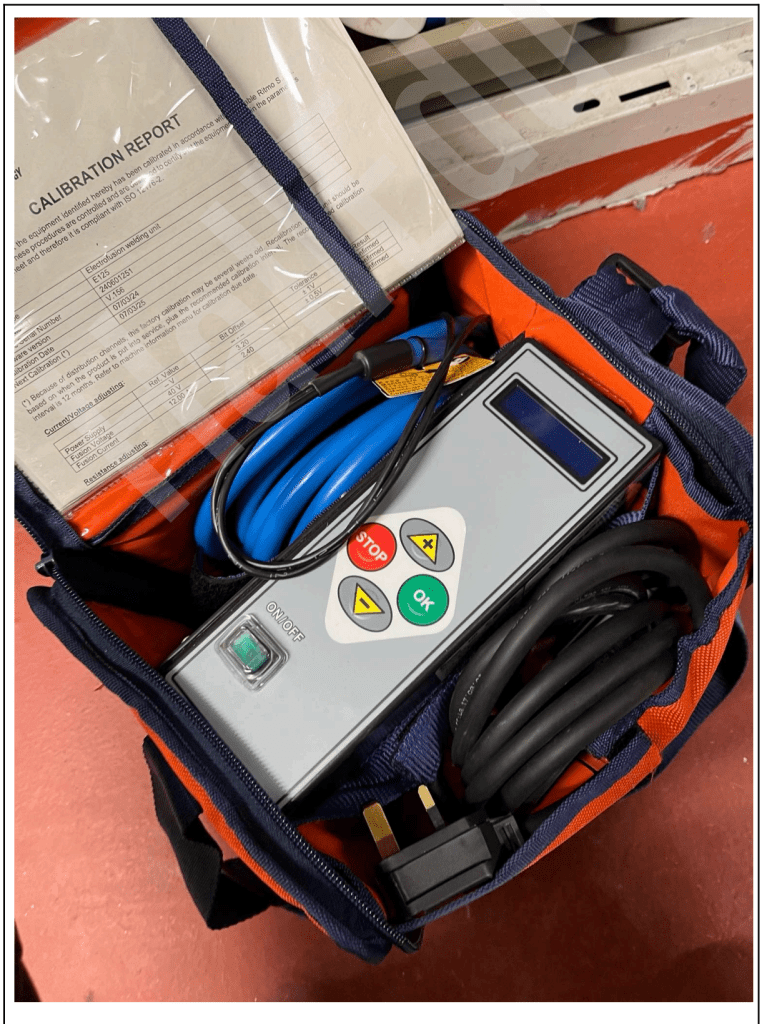

St 8 – GSHP – ground loop tools, specialist kit. Making of fusion welding joints and installation of ground loops. (Skills Task – Behaviour Combined Task) St and BCt

(Skills Task – Behaviour Combined Task) St and BCt

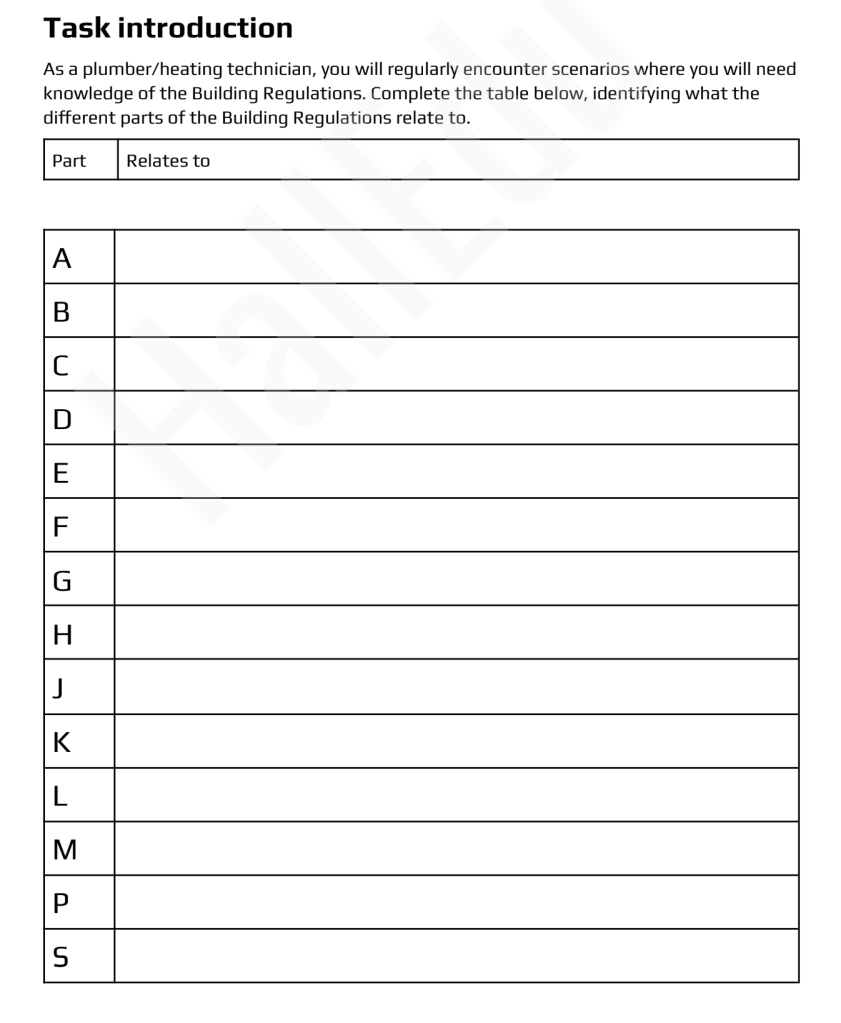

St 10 – Building regulations associated with the Industry and why, when and how they are used? (Skills Task – Behaviour Combined Task) St and BCt

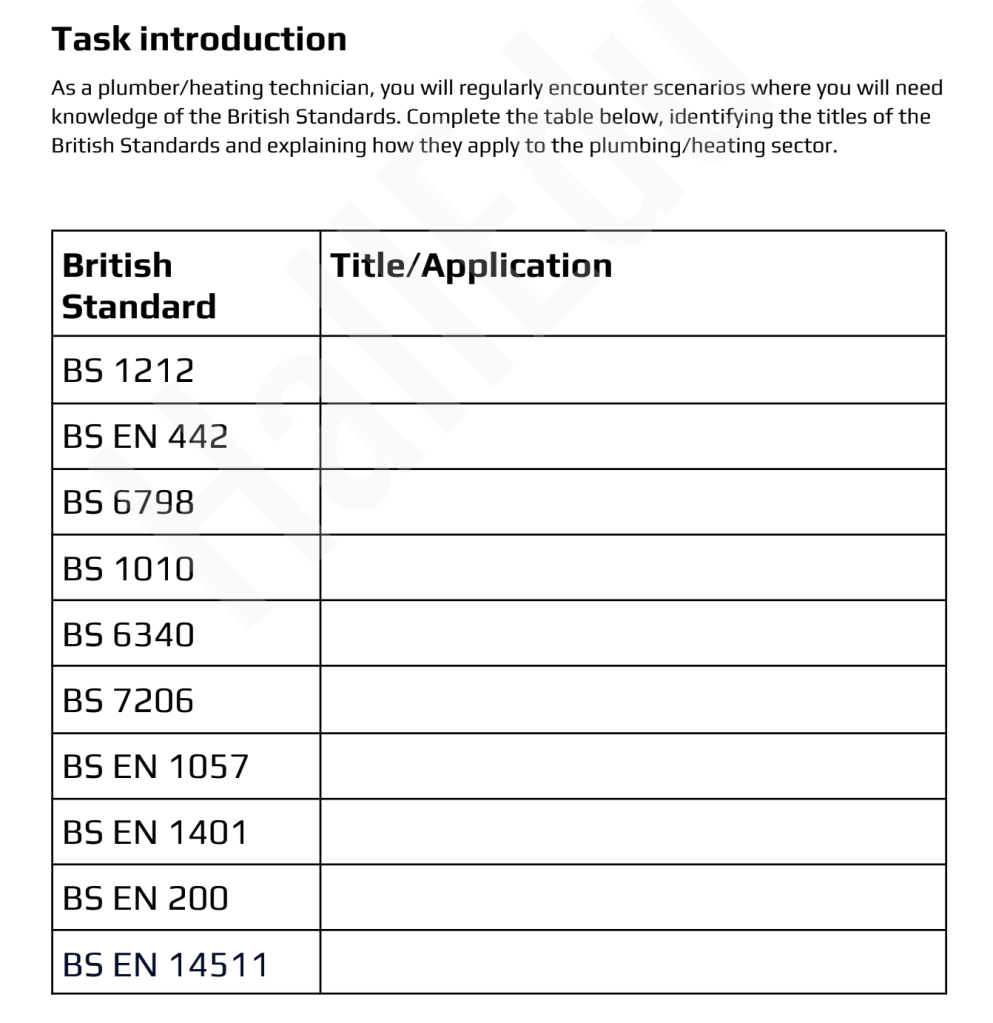

St 11 – British Standards associated with the Industry and why, when and how they are used? (Skills Task – Behaviour Combined Task) St and BCt

St12 – More pipe sizing using prior learning bringing things together using mass flow rate triangles. (Skills Task – Behaviour Combined Task) St and BCt

St 13 – Breadth and Depth of heat loss/transfer scenario design and sizing of source of heat and emitters. (Skills Task – Behaviour Combined Task) St and BCt

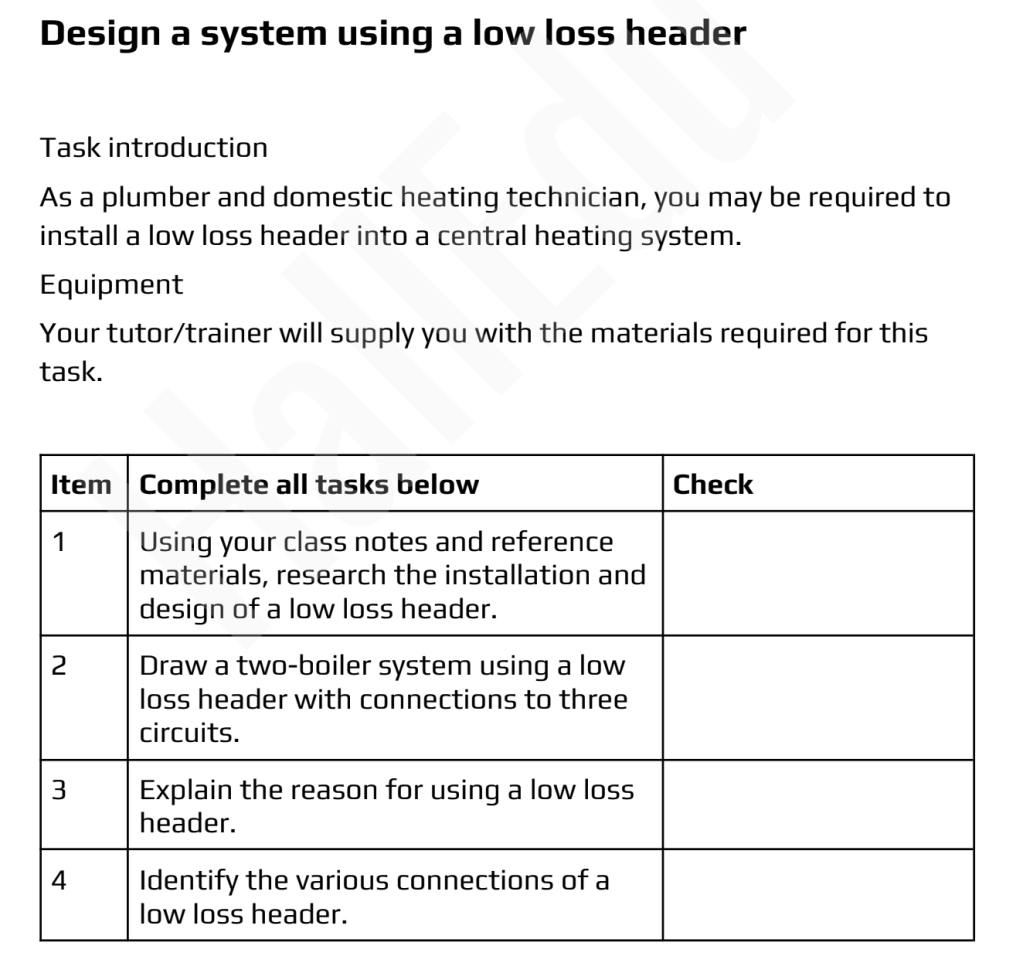

St 14 – Hydraulic separation design using St 13 as the system scenario.

(Skills Task – Behaviour Combined Task) St and BCt

St 15 – Simple pipe classification and identification research and task to use the results with a scenario. (Skills Task – Behaviour Combined Task) St and BCt

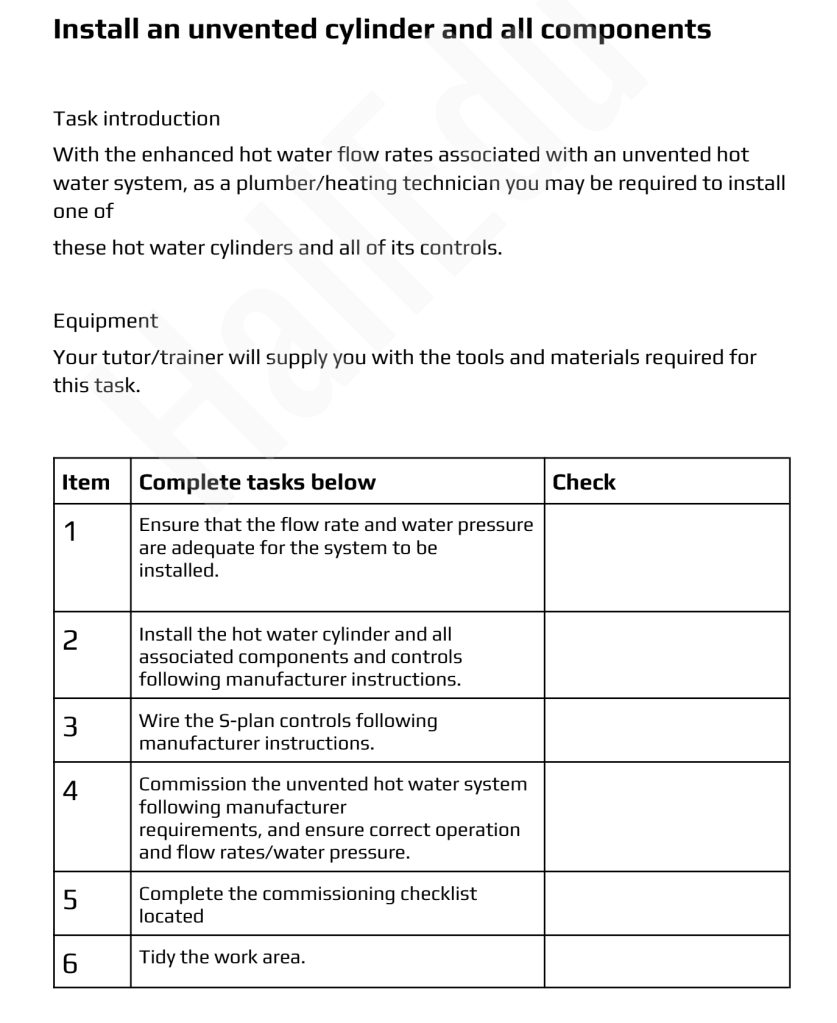

St 16 – Installation of an Unvented hot water cylinder x 2, in accordance with MI’s and part G3 compliant. Checking breadth and depth of knowledge/skills. Using both inlet methods of combination valve and valves in series.

(Skills Task – Behaviour Combined Task) St and BCt

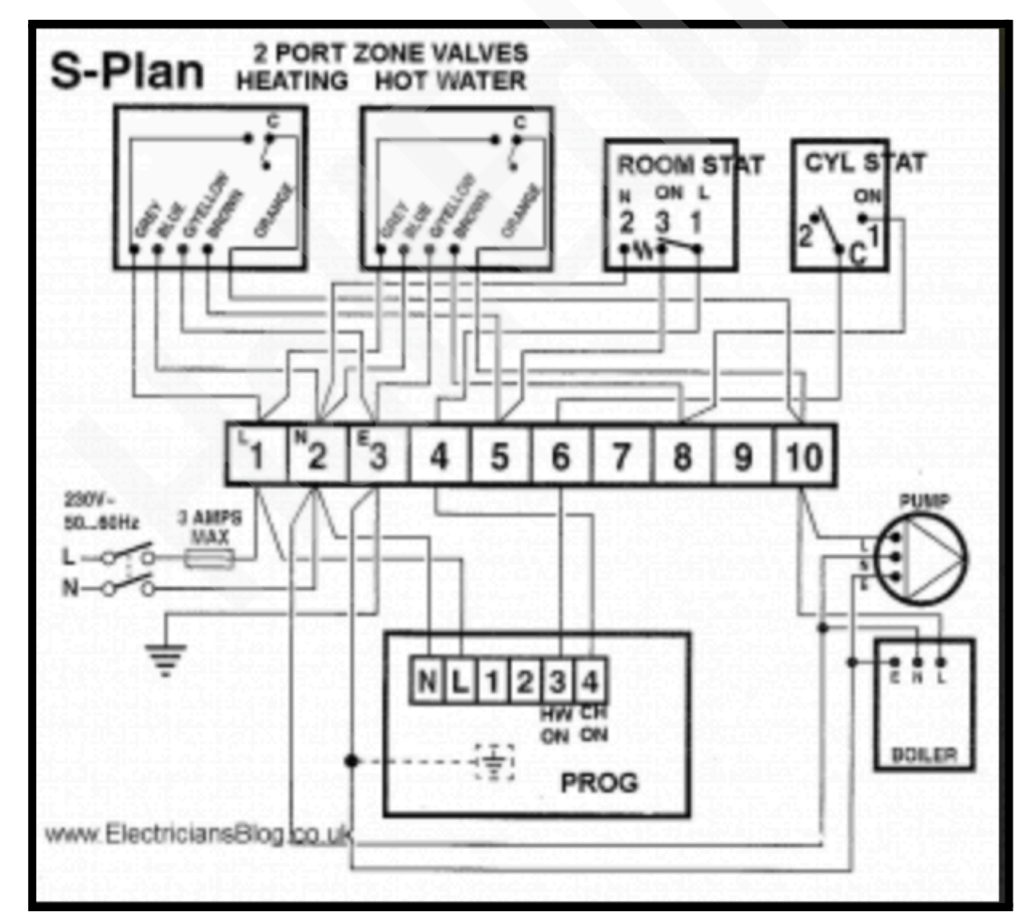

St 17 – System wiring linking with St 16 and completing the wiring of an S plan and S plan +

(Skills Task – Behaviour Combined Task) St and BCt

St 18 – Electrical testing and basic trouble shooting on St 17 systems.

(Skills Task – Behaviour Combined Task) St and BCt

St 19 – Documentation – recording data and communication.

(Skills Task – Behaviour Combined Task) St and BCt

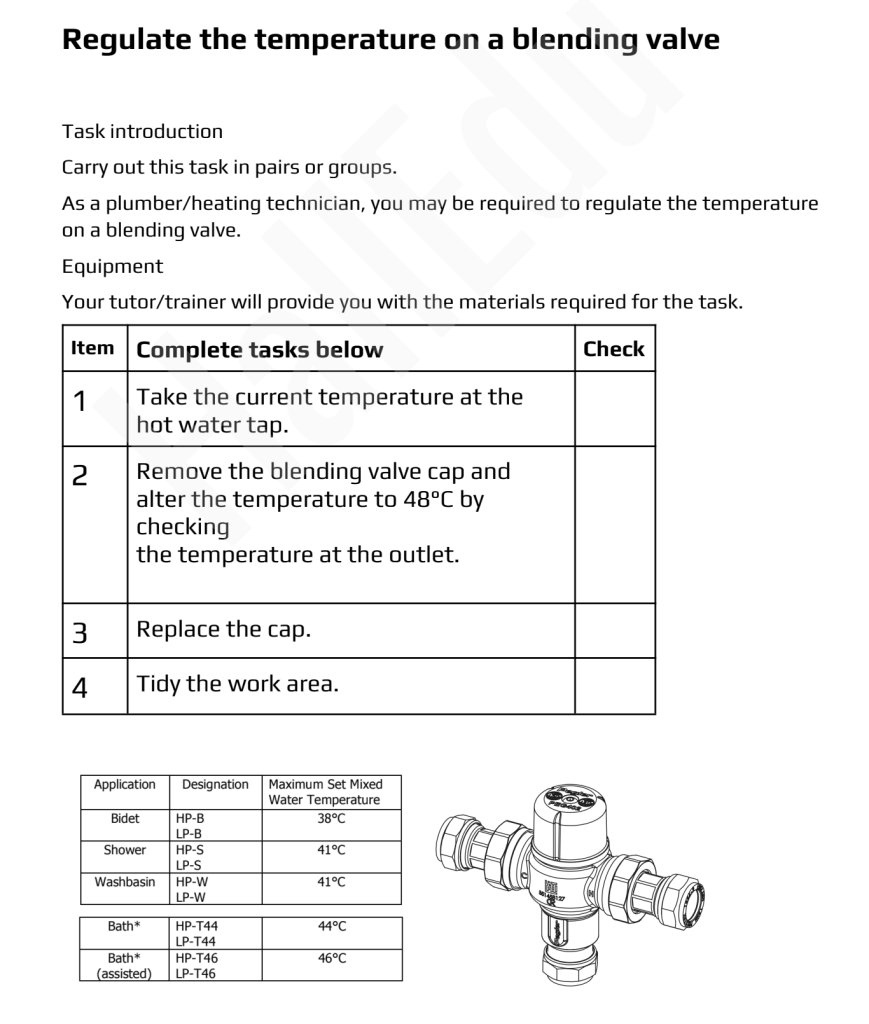

St 20 – Controls of hot water temperatures in domestic and public buildings.

(Skills Task – Behaviour Combined Task) St and BCt

St 20a – Installation and control of hot water outlets via blending valves and record temperatures using Industry tools and equipment on TMV2 and TMV3.

(Skills Task – Behaviour Combined Task) St and BCt

St 21 – Review and revisit items that require further study after discussion and feedback conversations. (Skills Task – Behaviour Combined Task) St and BCt

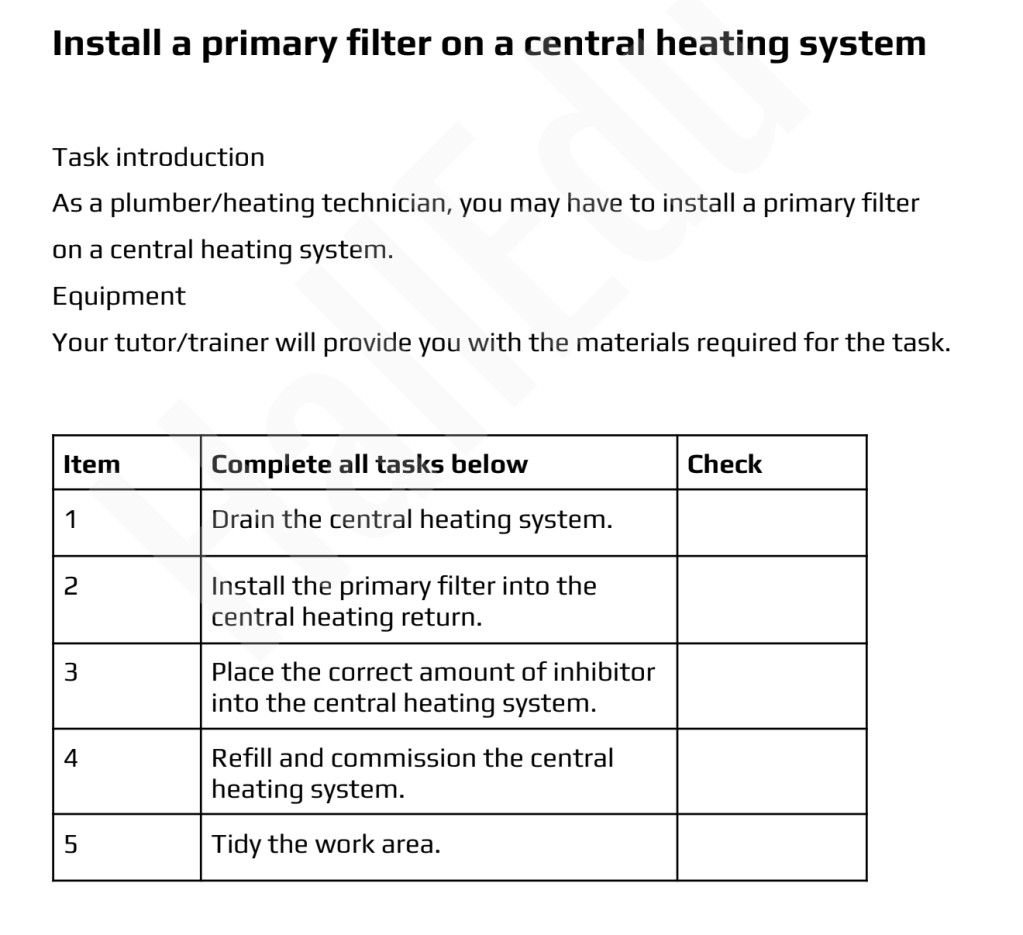

St 22 – De-commissioning of a domestic system in readiness for low temperature heating and hot water installation. (Skills Task – Behaviour Combined Task) St and BCt

St 23 – Replacement of components on system, adding additional components to systems. (Skills Task – Behaviour Combined Task) St and BCt

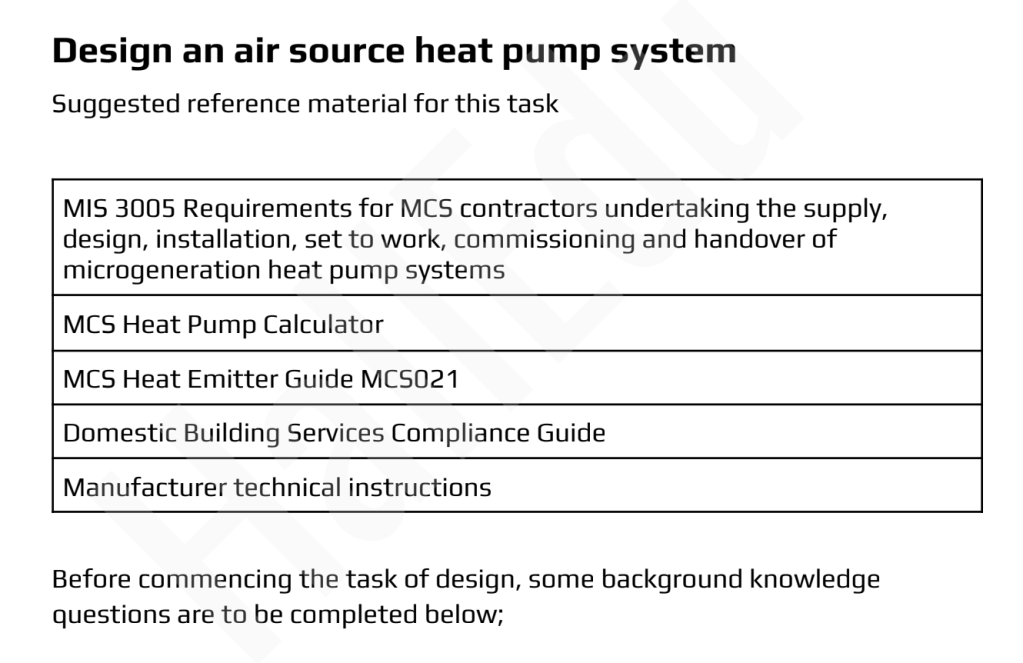

St 24 – Design considerations and requirements for ASHP’s.

(Skills Task – Behaviour Combined Task) St and BCt

St 25 – Linking with St 24 to undertake a DNO application. Use the appropriate documentation. This is for a property offered via a scenario. (Skills Task – Behaviour Combined Task) St and BCt

All of the above are Skills that the apprentice will be trained on. They will constantly refer back to year one learning. At the same time, they will build new skills and knowledge during the year two training plan. The KSB’s should be built regularly. They should be repeated. This allows the apprentice to become confident, comfortable, and fluent in all areas of the apprenticeship standard.

Leave a comment