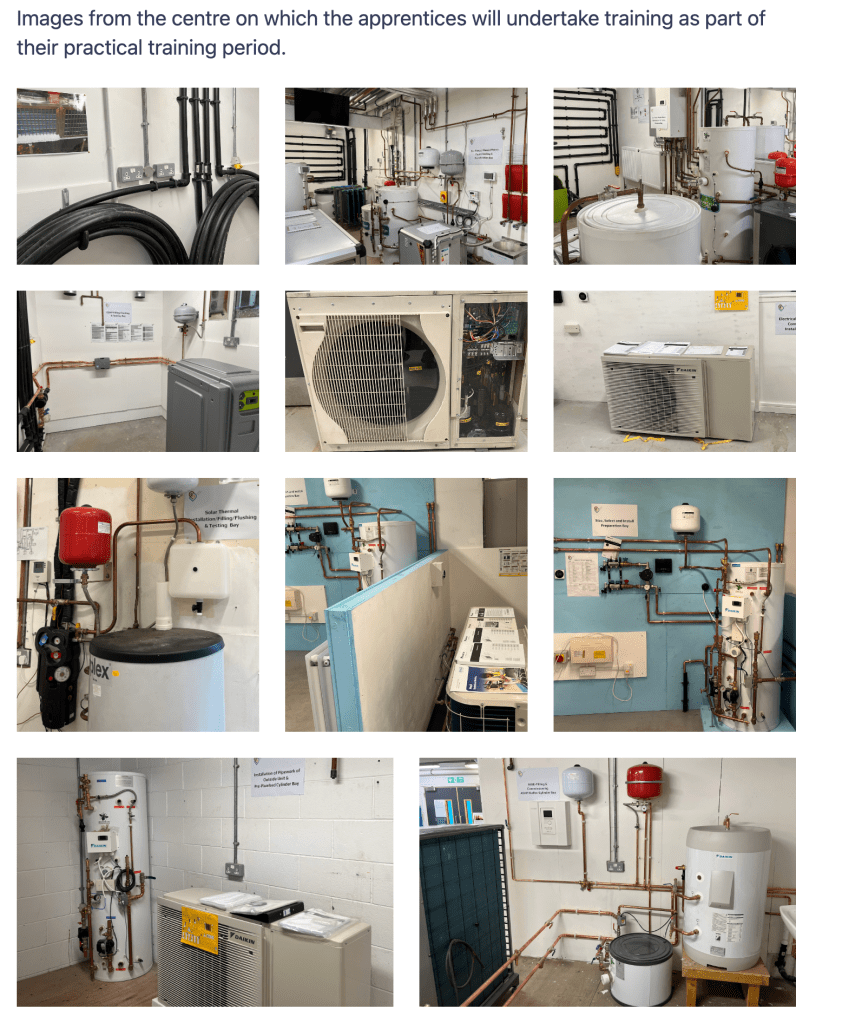

Update on progress – Week 5 is now in the books on the #LCHT apprenticeship standard and great progress is being made. All of the apprentices are engaged in the practical training via the training pack.

The practical training pack consists of various sections which can be seen below. Within each section are the following;

Safe working practices-

- Hazard spotting

- Risk assessments and method statements

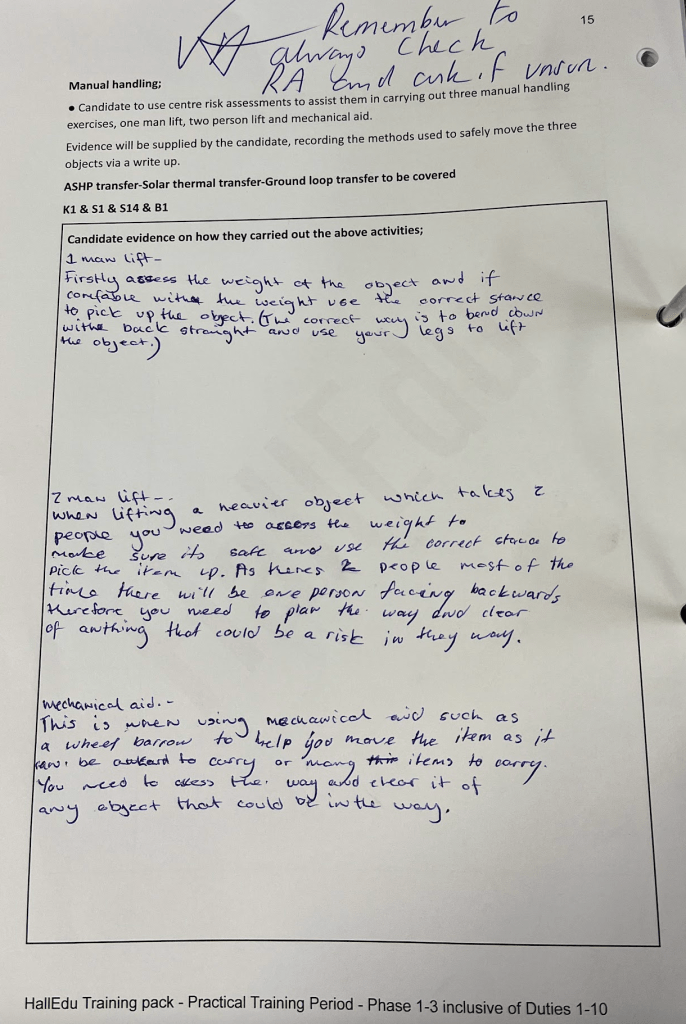

- Manual handling

- PPE kit

- Access equipment

- Hot works and fire fighting

- Working with hazardous materials

- Safe working with electrical appliances/tools

Common installation processes and techniques-

- Identification of a range of fittings from the sector

- Measuring and recording dimensional information accurately

- Fabrication of copper tube and fixings

- Fabrication of CSST, LCS and Plastic tubes

- Jointing methods of all materials

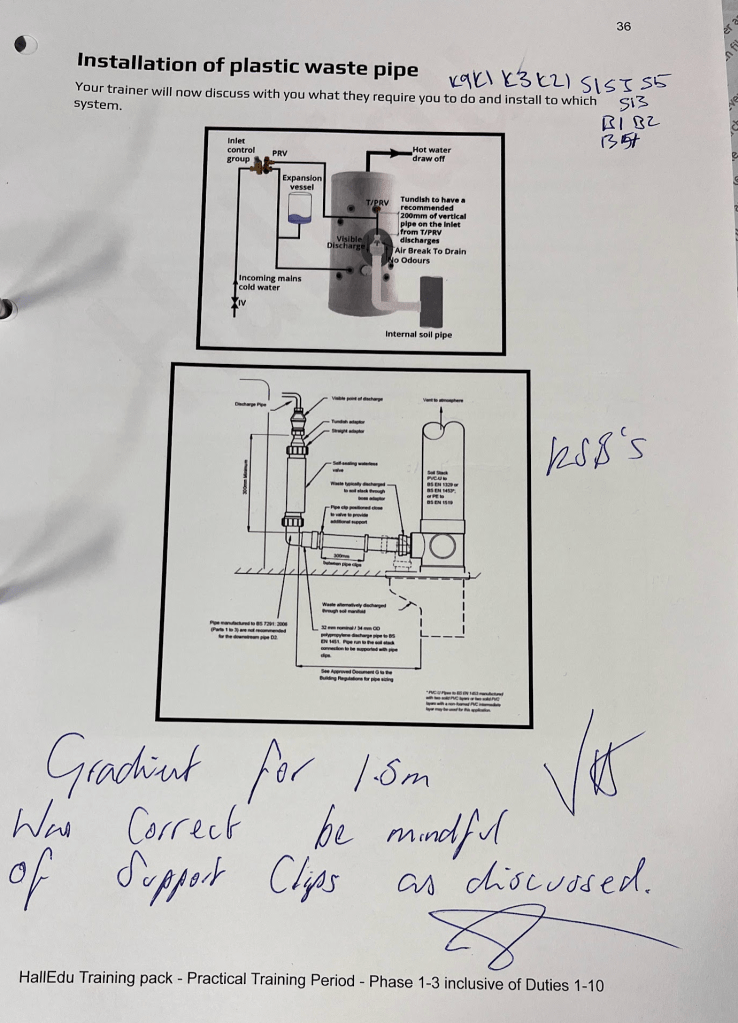

- Identification/Installation of waste pipe used for hot water and heating installations

- Identification of waste pipe fittings

- Installation of waste pipe to low carbon and hot water systems

- Safe soldering, fusion welding techniques

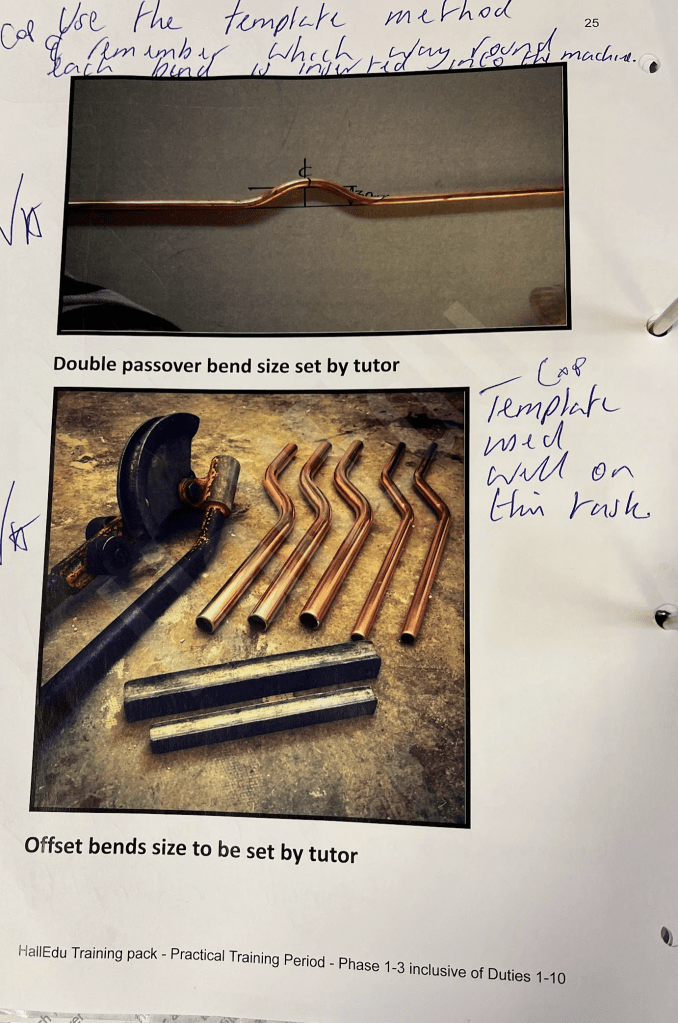

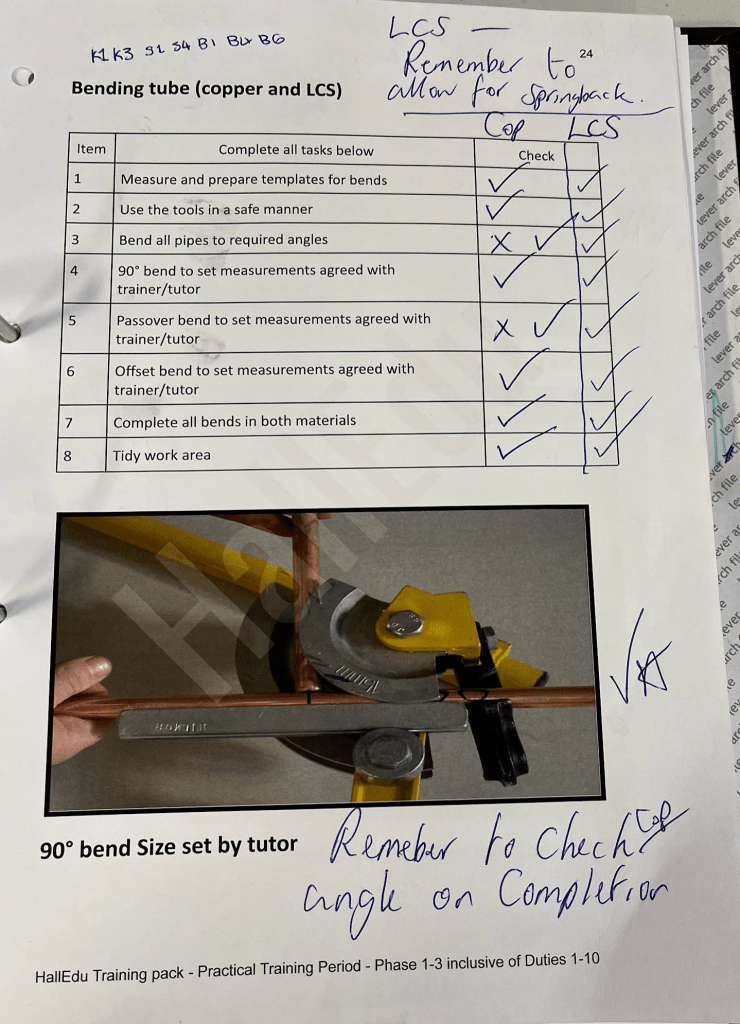

- Bending of copper, LCS, and CSST pipe

- Module installation tasks bringing skills together

- Installation of a range of heat emitters

Electrical work and controls-

- Electrical component and tool identification

- Safe isolation of circuits/appliances

- Electrical wiring of flex/cables

- Testing, short circuit, continuity and polarity

- Electrical wiring of controls and components found on low carbon and hot water systems

- Fault finding on electrical circuits/components

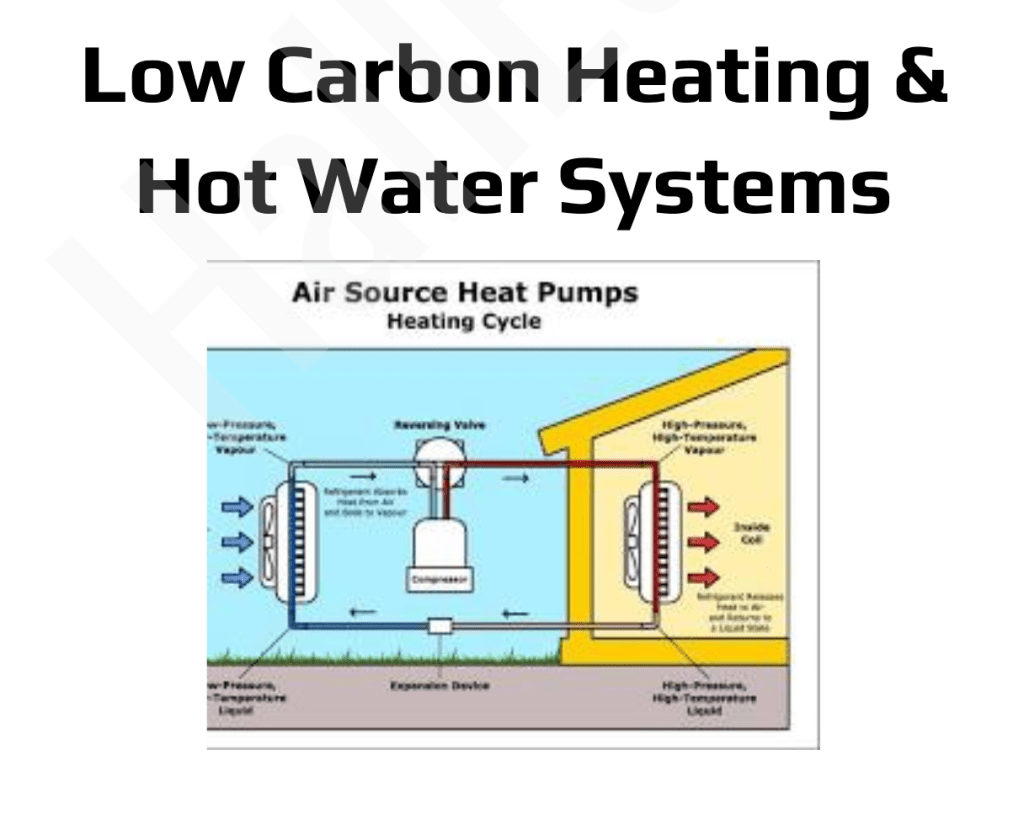

Low carbon heating and hot water systems-

- Building regulation tasks to identify relevant regulations in low carbon and hot water systems

- British Standards tasks to identify relevant British Standards in low carbon and hot water systems

- Pipe sizing tasks – heat output to emitters and correct pipe sizes

- Heat loss/transfer calculations and how to use them in low carbon and hot water system design

- Low loss header design and installation

- Installation and planning of an unvented cylinder/buffer/volumiser used on low carbon and hot water systems

- Regulating temperature via blending valves, installation and service

- Installation of a filter on a low carbon heating system

- Installation of UFH systems and adjusting flow rates

- Design of an ASHP

- DNO task using scenario based activities

- Install main components of an AHSP

- Completion of all relevant paperwork for the installation including pre-installation, post installation and handover

- Servicing and maintenance records on ASHP

- Fault finding and rectification on ASHP systems

- Design of an GSHP

- DNO task using scenario based activities

- Install main components of an GHSP

- Completion of all relevant paperwork for the installation including pre-installation, post installation and handover

- Servicing and maintenance records on GSHP

- Fault finding and rectification on GSHP systems

- Design of an Solar Thermal installation

- Install main components of an a Solar Thermal installation

- Completion of all relevant paperwork for the installation including pre-installation, post installation and handover

- Servicing and maintenance records on a Solar Thermal installation

- Fault finding and rectification on Solar Thermal systems

- Employer and industry led bespoke training at any phase as directed by the employer

- Site survey scenario tasks

Classroom activities-

- Safe working

- Processes

- Scientific principles

- Planning and supervision

- Low Carbon systems

- Cold water systems

- Hot water systems

- Electrical systems and components

- Employer and industry special delivery

- F gas awareness

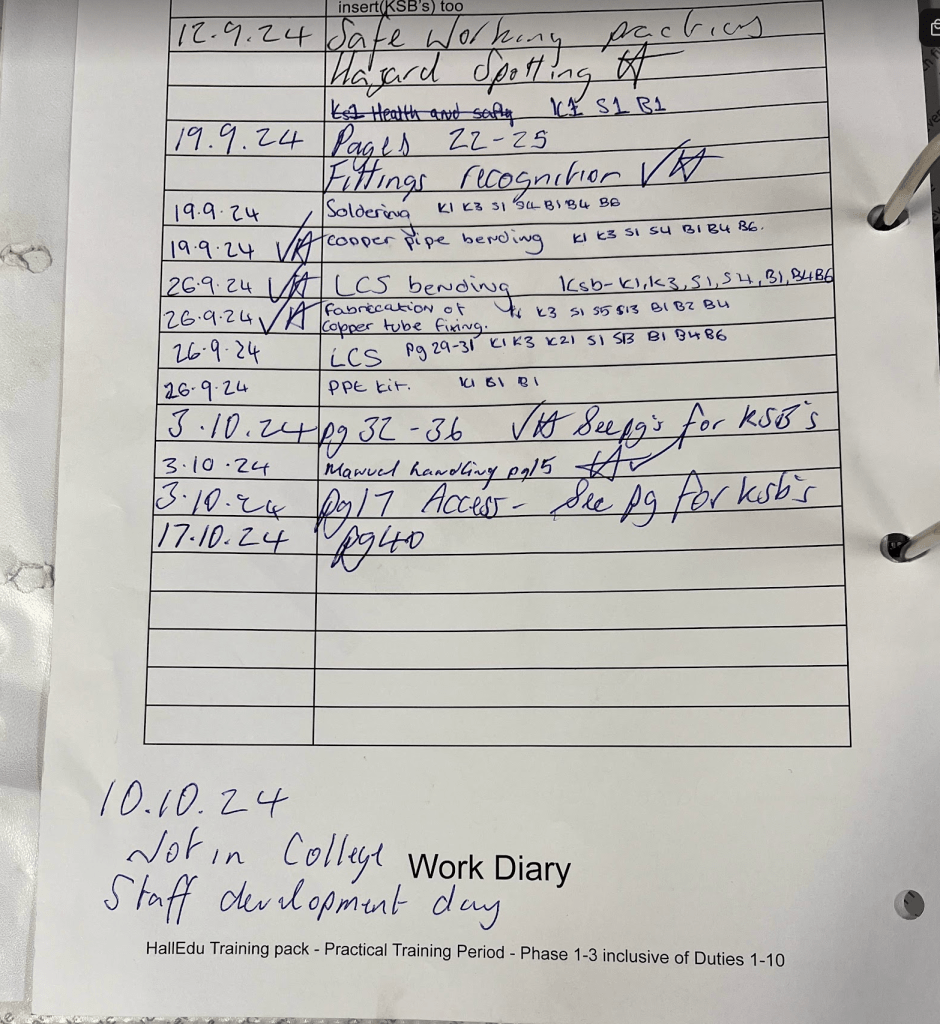

All of the above are monitored and assessed for knowledge and mapped to the KSB’s with the apprentices recording the KSB’ that they have been working at during the sessions see images in the blog that showcase an apprentices practical training pack with their linking of KSB’s to the task.

KSB’s recorded in apprentice practical training pack with KSB’s as they move through the training tasks. Below is a video from week 1 of the #LCHT with the apprentice recalling their tasks they completed at work that week and then transferring and mapping the content to their work log, this along with the KSB mapping in centre during the practical tasks makes the apprentice become fluent in the practice in readiness for when they get ready to produce their 10 job work log for gateway to EPA.

Leave a comment