Wonderful sessions have taken place at Bolton College working with Bolton at Home staff who requested a heat pump fault finding and rectification course to be developed, to enable their skilled staff to be even more adept at identifying the issues that they may come across in their day to day work when attending properties with this technology installed. The training afforded the attendees the confidence to be able to share the knowledge and pass on the information to the tenants of the B@H properties in order to get the best outcomes in the use of the units/systems. It was requested by the M&E manager during the launch of the LCHT apprenticeship standard, that this sort of training would be beneficial. The college staff responded to this request with the support of Andrew Louth from Groundtherm Andrew attended the training sessions and supported and trained the B@H staff with the training that was devised by Bolton College I worked with Andrew on the delivery too, it was very fulfilling to see the reaction from the engineers of how the training which was a real hands on experience benefitted them and enhanced their knowledge, all in attendance over the three course run so far have offered extremely positive feedback. More are planned to be run at the college in the near future following such positive feedback.

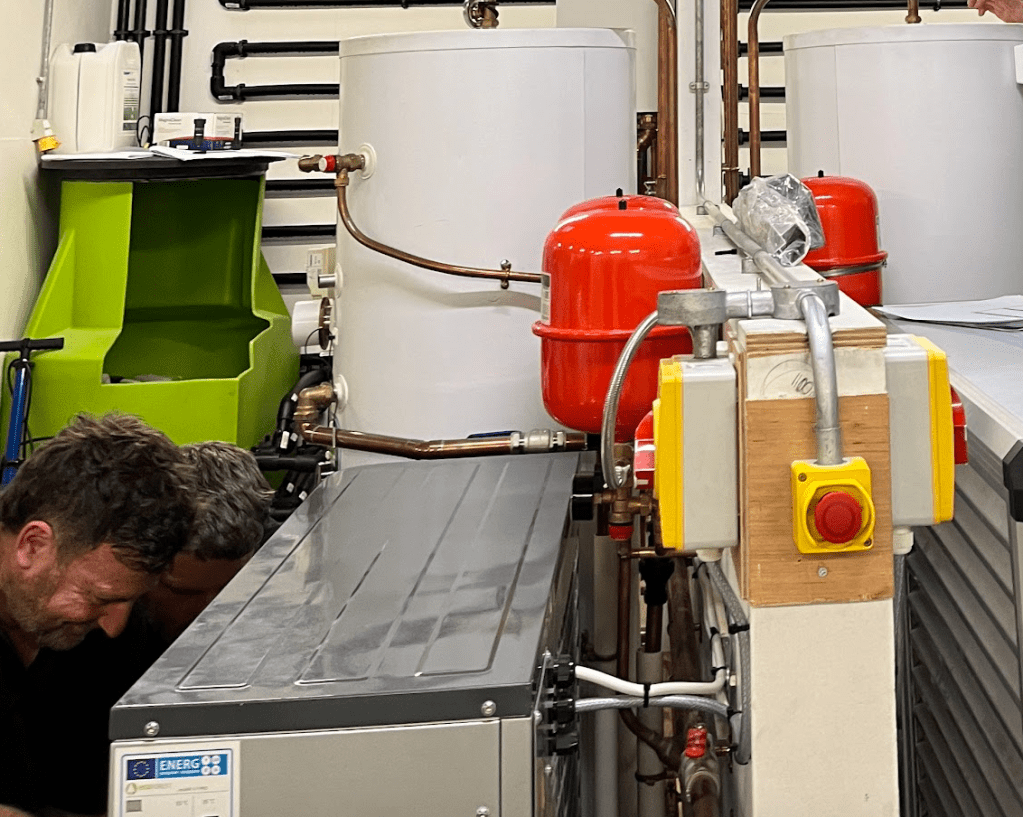

Some engineers from Bolton at Home actively engaged in locating the faults on the ASHP system via the control panel and rectifying and checking functionality after the alterations/repairs.

More Bolton at Home engineers working to identify and repair faults on an ASHP during the course.

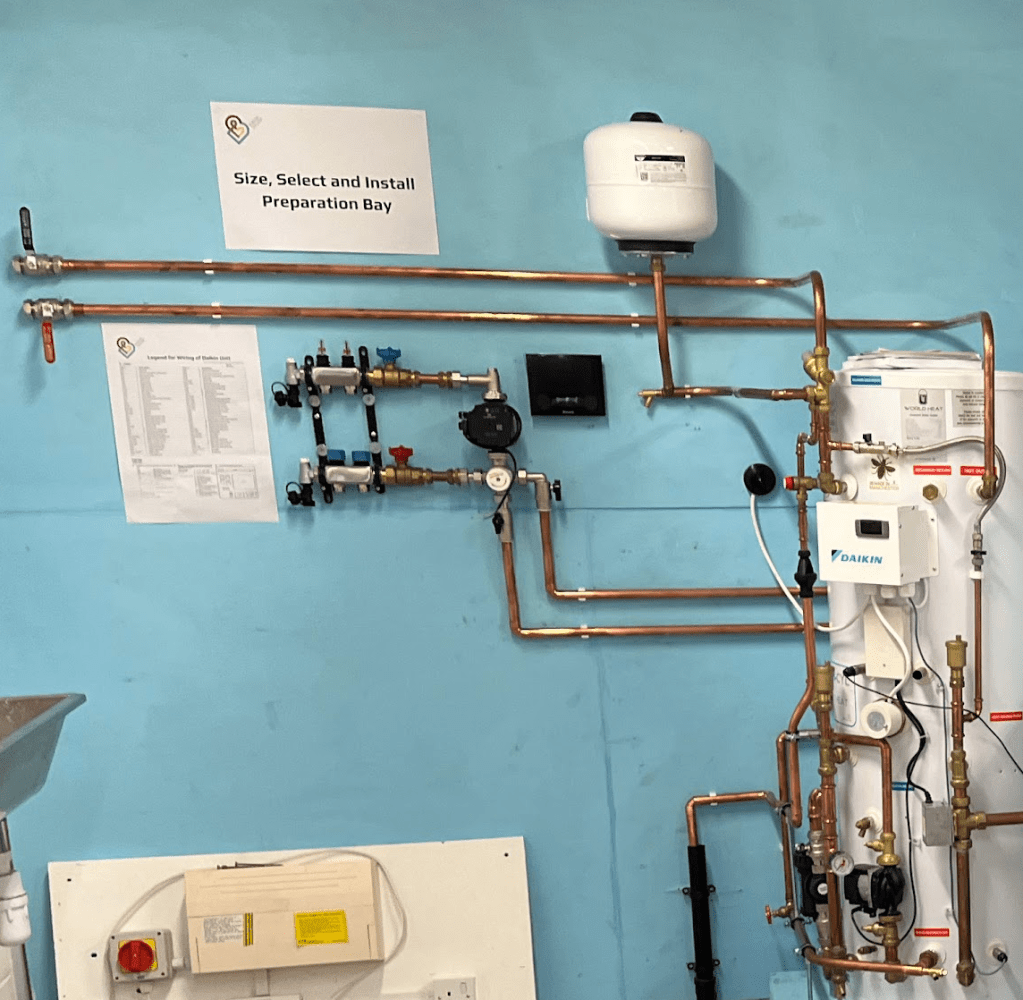

Part of a training rig for the candidates to familiarise them with components and layouts as a recap of prior learning as all attendees already have a qualification for ASHP installation.

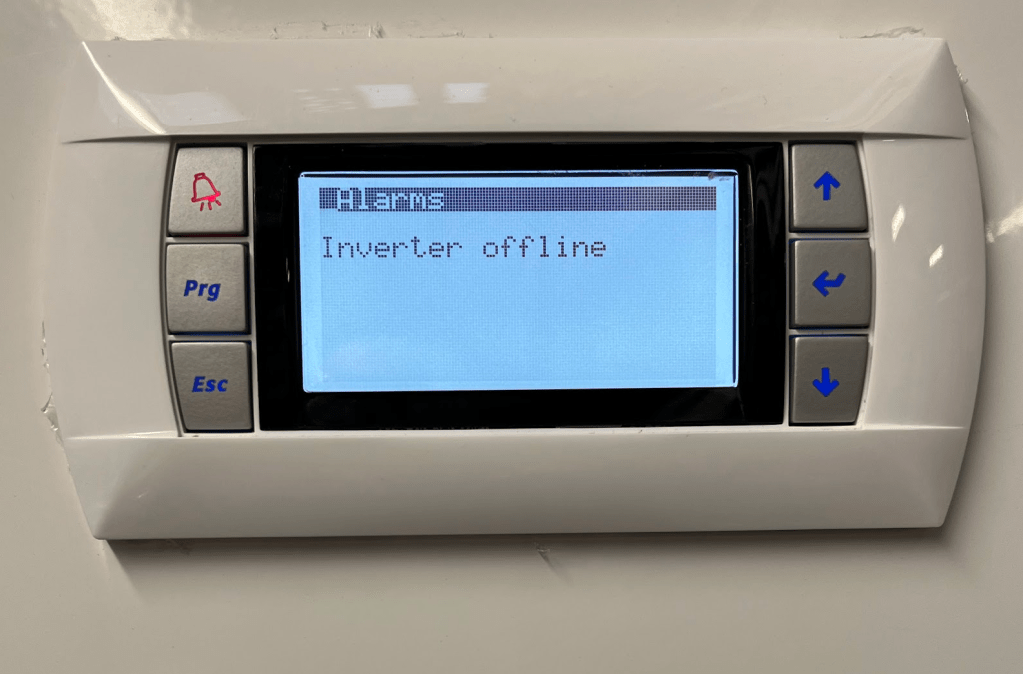

Image of an alarm log that the candidates saw and rectified

PCDX unit being changed to rectify and check faults/repairs

All attendees took part in active learning during the course covering a range of relevant tasks required to enable engineers to apply the skills in the field:

- Inspection of a system and the OU

- Servicing of a system and the OU

- Service and fault finding on a range of heat pumps/systems and control interfaces

- Discussions with Industry expert during the day as questions were raised during the practical activities, using their experiences from the workplace

Some examples of feedback from the course

What were your key takeaways from this event?

good working knowledge

A better understanding of how air source connects onto a standard heating system. It’s not usually the unit thats faulty, it’s the system its connected to. Flow is king

More confident

An Understanding of workings more thoroughly

Any overall feedback for the event?

Good day, very informative

It was great, real talk about real heating systems

Enjoyed it, interesting and very helpful

Leave a comment